Design Build

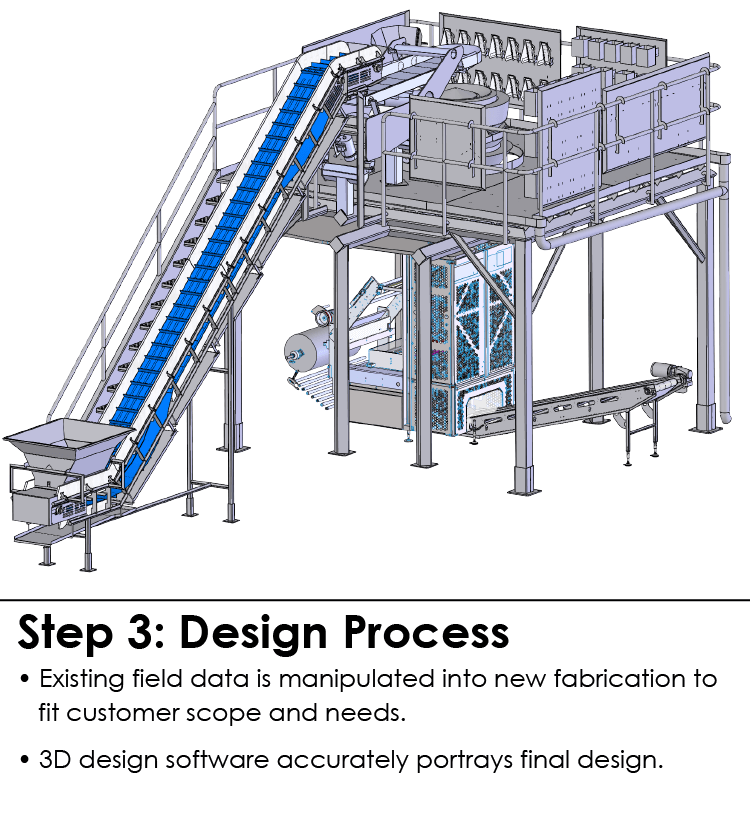

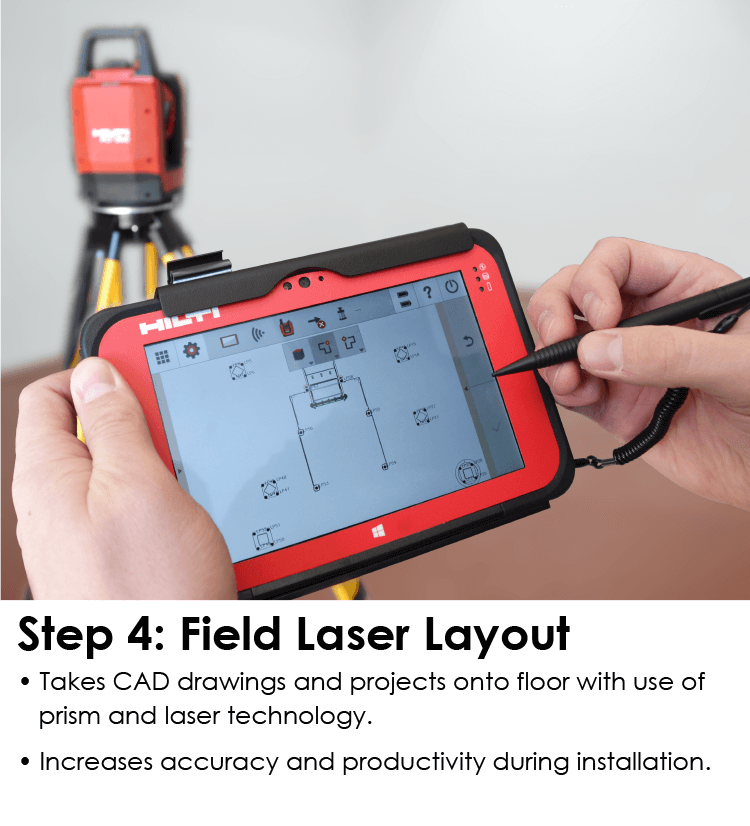

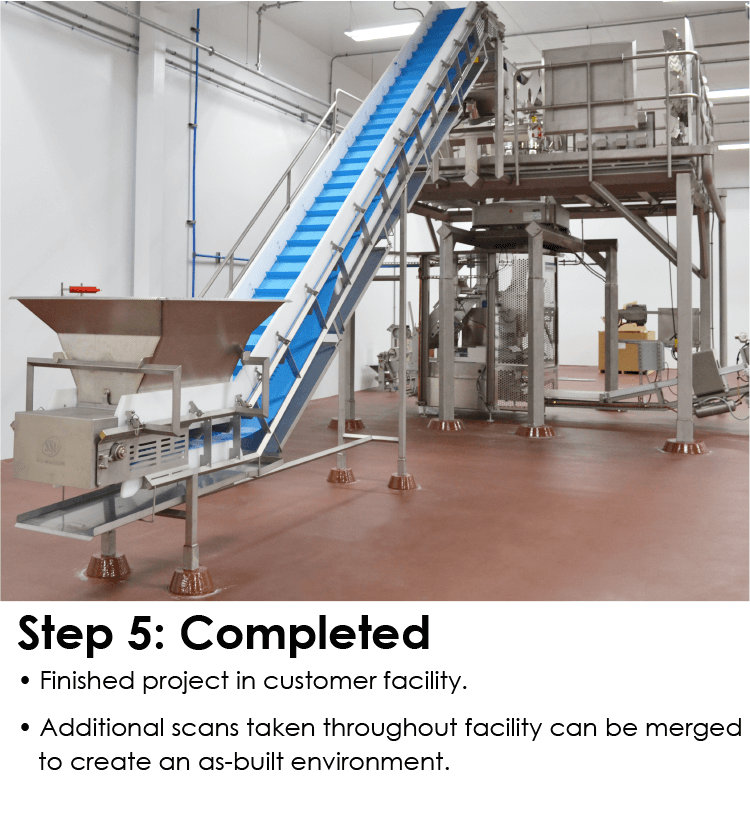

Stainless Specialists, Inc. has been partnering with customers on design build projects for over 30 years. This includes new 3D scanning, laser layout capabilities, plant layouts, existing line retrofits and as-built drawings. Utilizing new industry technologies, projects can be completed with reduced project timelines. Tackling design, fabrication, and equipment installation, customers are able to keep projects under one roof.

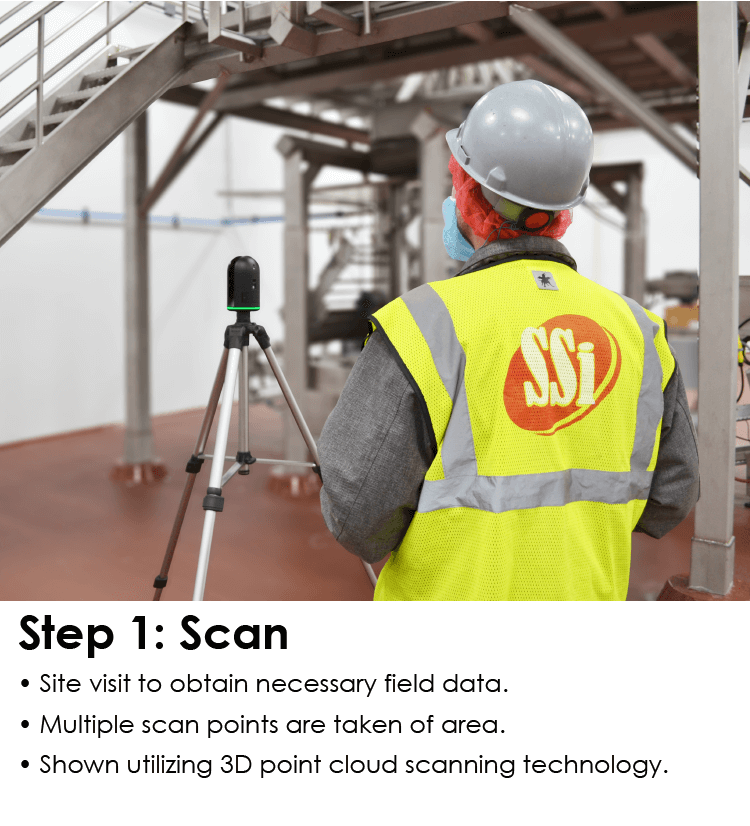

Scanning Advantages

- Can take place while plant is in operation while still maintaining accuracy

- Process can gather data in a matter of hours vs. weeks

- Reduces return visits for missed measurements

- Can reduce field labor and minimize plant down time during installation

Testimonial

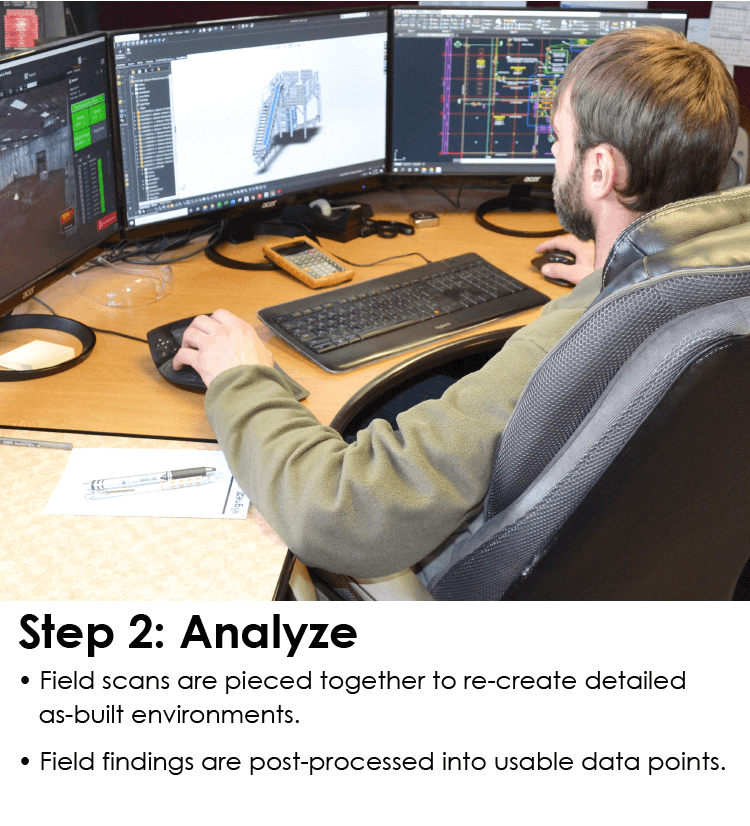

“I’ve had the pleasure of working with SSi as a project manager on two sizeable

design/build contracts in a large potato processing facility in the Northwest. SSi used

state-of-the-art scanning tools to create 3D models of the existing areas. They also

created 3D design models of the new equipment and laid those into the existing areas.

This design technique allowed extraordinary visualization of the proposed layout in the

existing areas. Using the models, we gained an exceptional review of potential conflict

points with equipment and personnel, and access points for plant personnel (operators,

maintenance, and sanitation). I would highly recommend SSi as a primary contractor for

many of your projects requiring 3D equipment design, equipment fabrication, OEM

equipment installation, and demolition/installation services.”– Bud Mandeville, Project Manager