Dewatering System

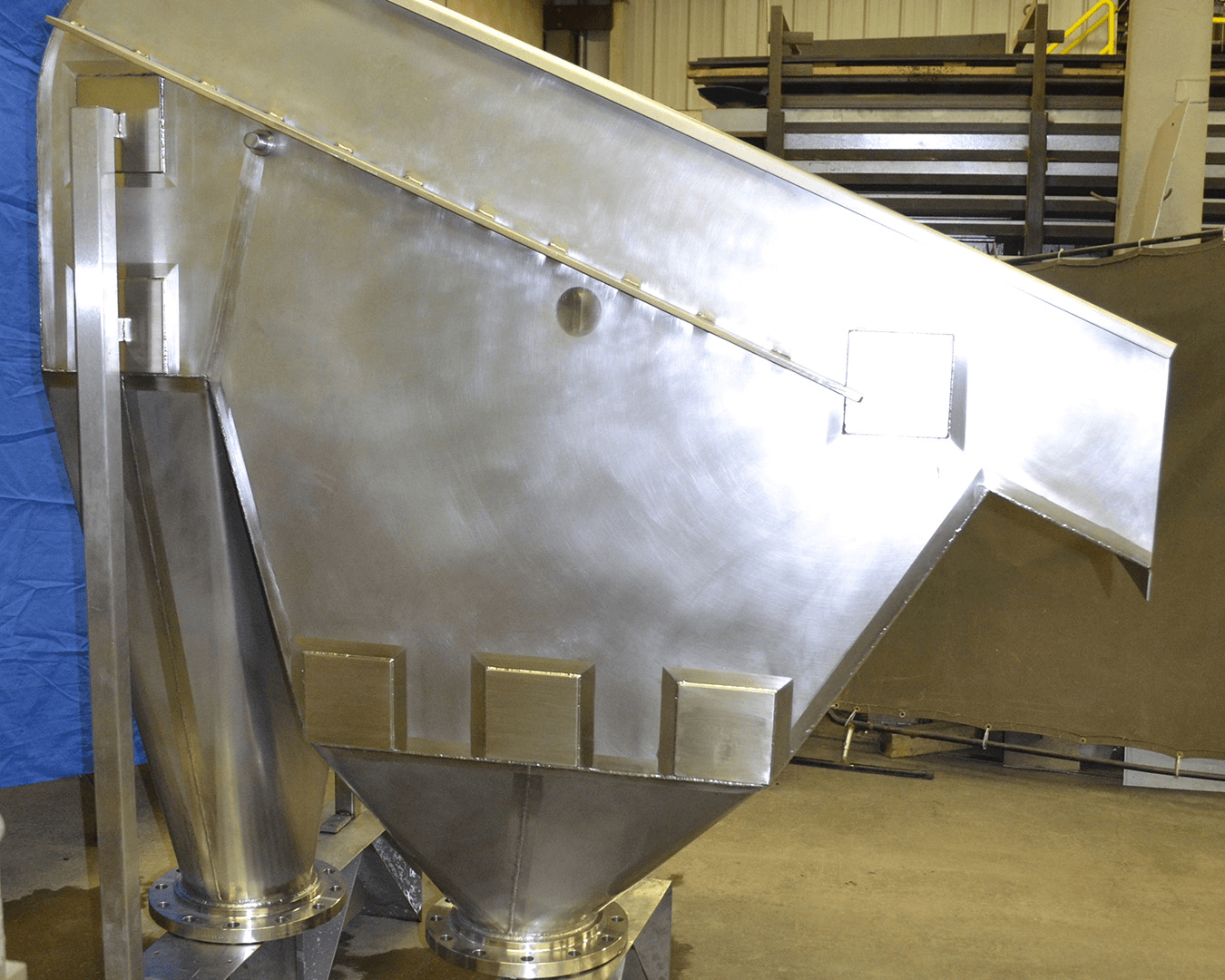

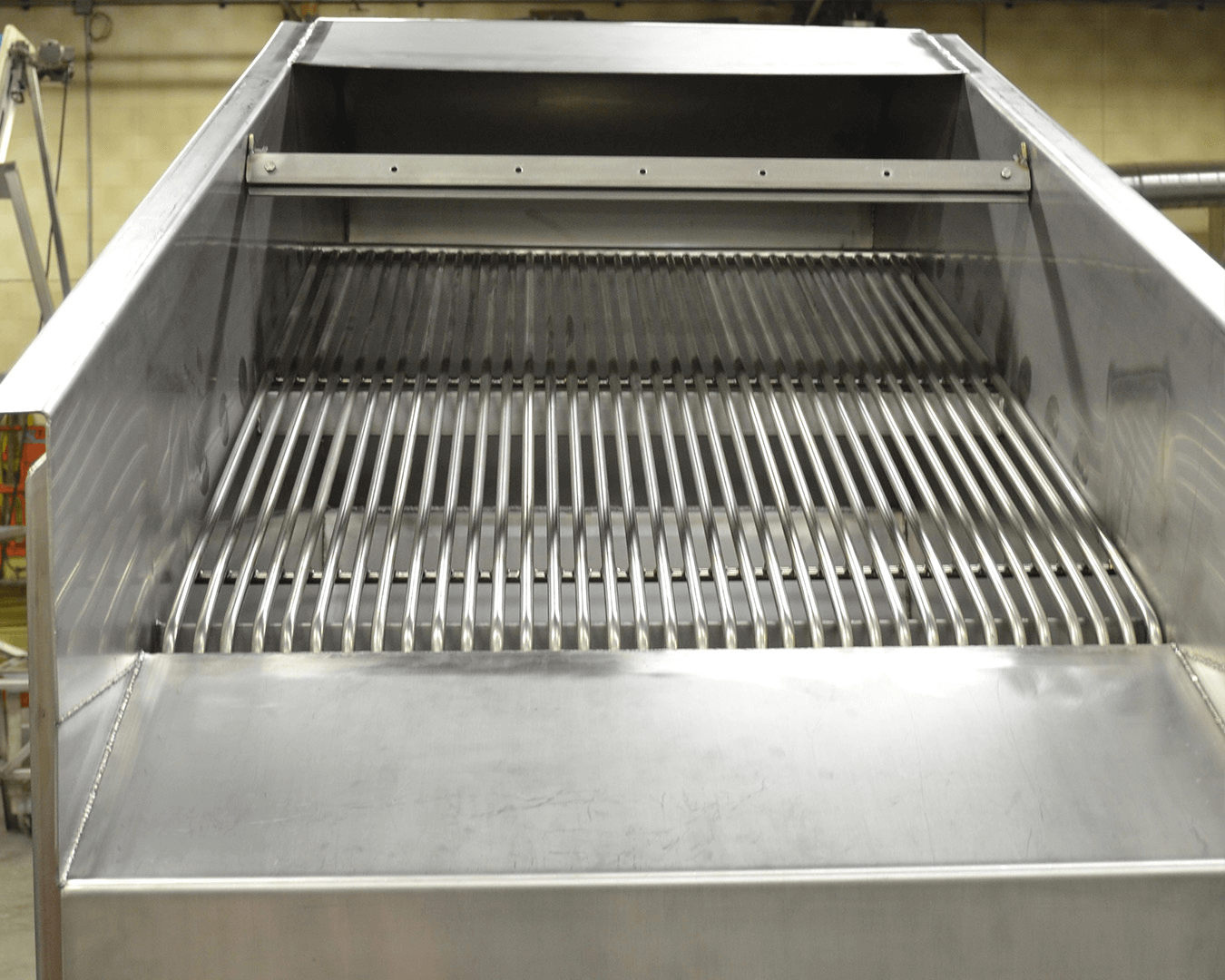

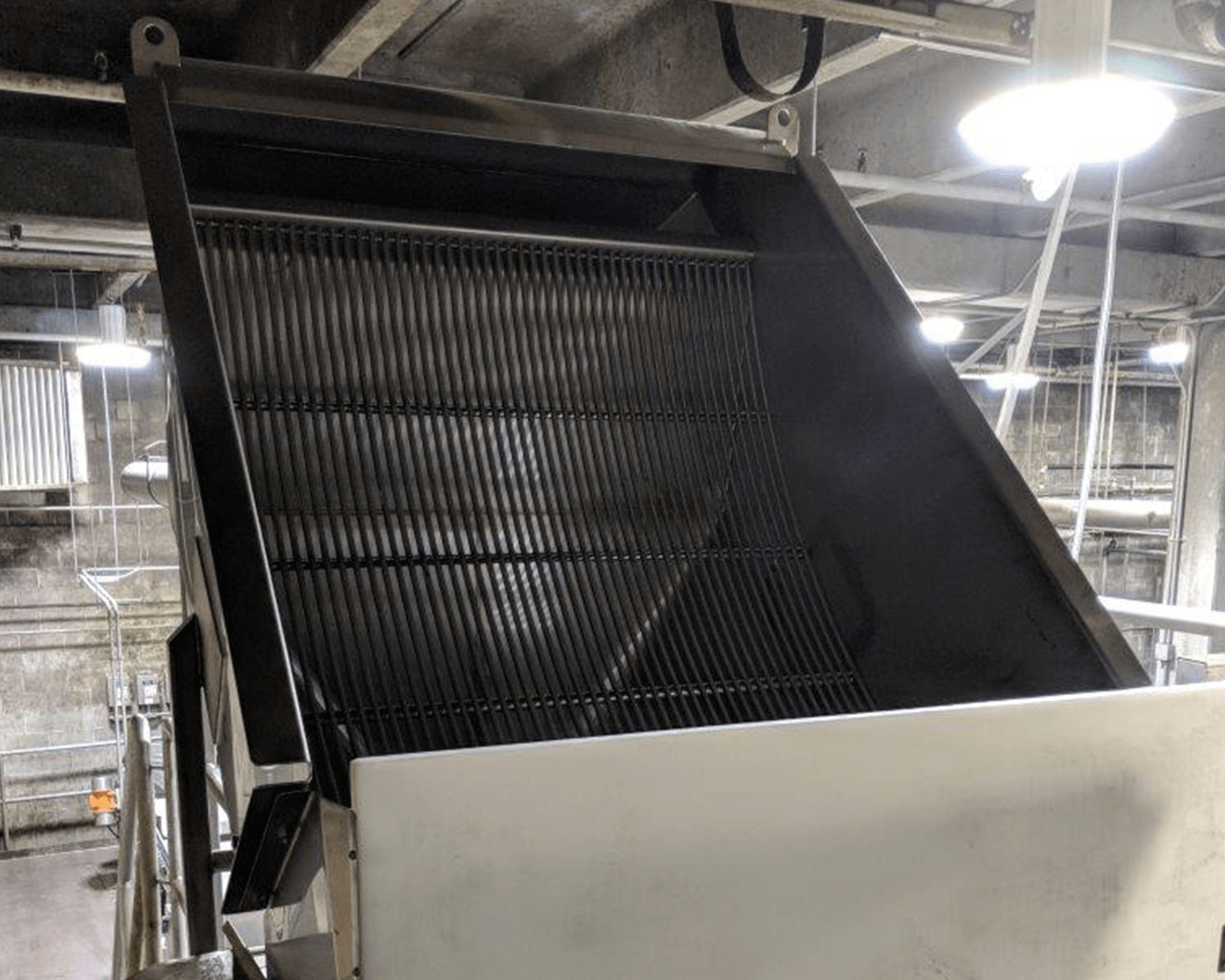

In processing environments where product is pumped from one area to another, water needs to be removed from the process. This can be accomplished a variety of ways, but the easiest most cost-effective way is by using a dewatering system. These systems are also sometimes called a dewatering grizzly or a dewatering screen. Product is pumped through a diffuser to slow it down as it enters the dewatering unit. The product is pumped across bars or wedge-wire which filter out the product but let the water fall back through the openings back to return. The product is then gravity fed into the next piece of processing equipment, where your operation continues.

Design Capabilities

- Designed per customer specifications (flow, product, etc.)

- Stainless steel 304 for washdown purposes

- Optional hinged dewatering screen to allow for better sanitation access

- No mechanical components for easy-to-maintain operation

- Easily dewater potatoes (cut or whole), beans, peas, corn or another similar products

- Built-to-last durable bars withstand product impact without any maintenance or issues