Paint Finishing Operations

With our many years of experience working on wet and powder painting systems, SSi is the preferred contractor for all your painting operation equipment. Our designers and fabricators are professionals when it comes to developing equipment used in positioning your part on your conveyor to create an easy-to-paint surface for your robots and manual painters. SSi addresses situations such as employee safety and facility operation costs when developing solutions for each system. We have proven experience in handling parts used in, but not limited to; boats, motorcycles, cars, ATVs, etc. What ever the part you need to paint, we can design and fabricate the fixture, part holding buffing station, conveyor line, and related equipment.

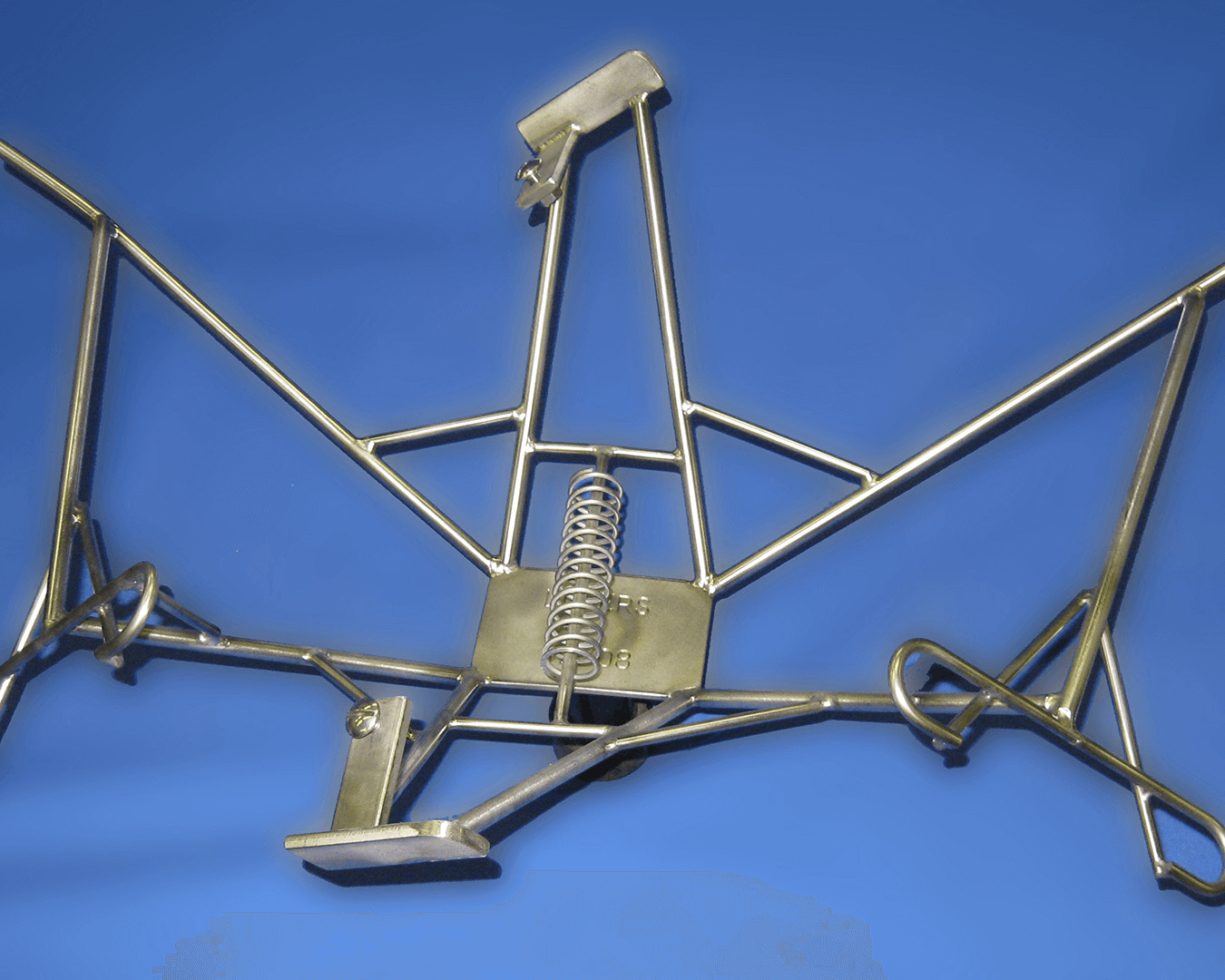

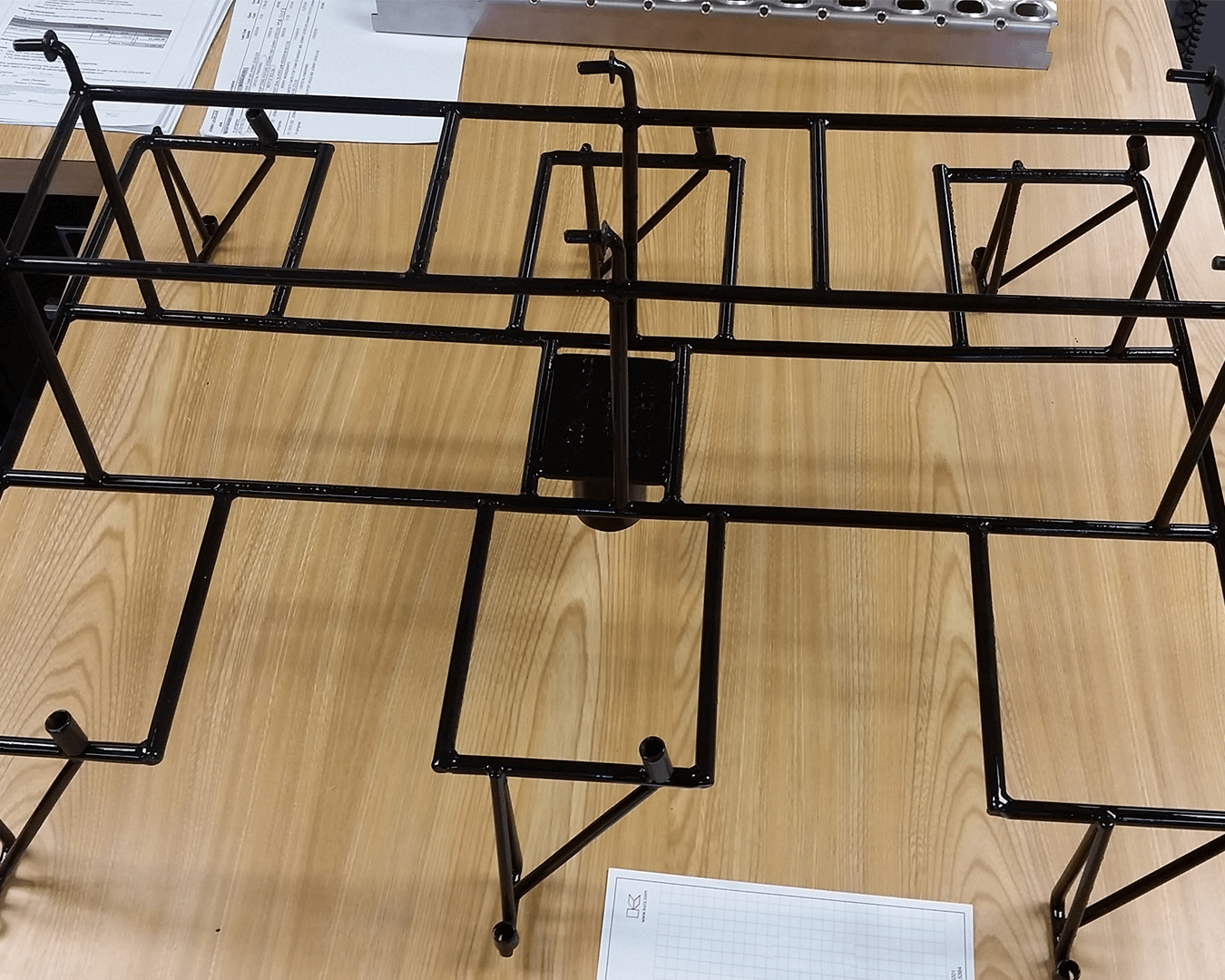

Paint Line Racks & Hooks

- Paint fixture fabrication and modification

- Pre-production prototyping with revisions

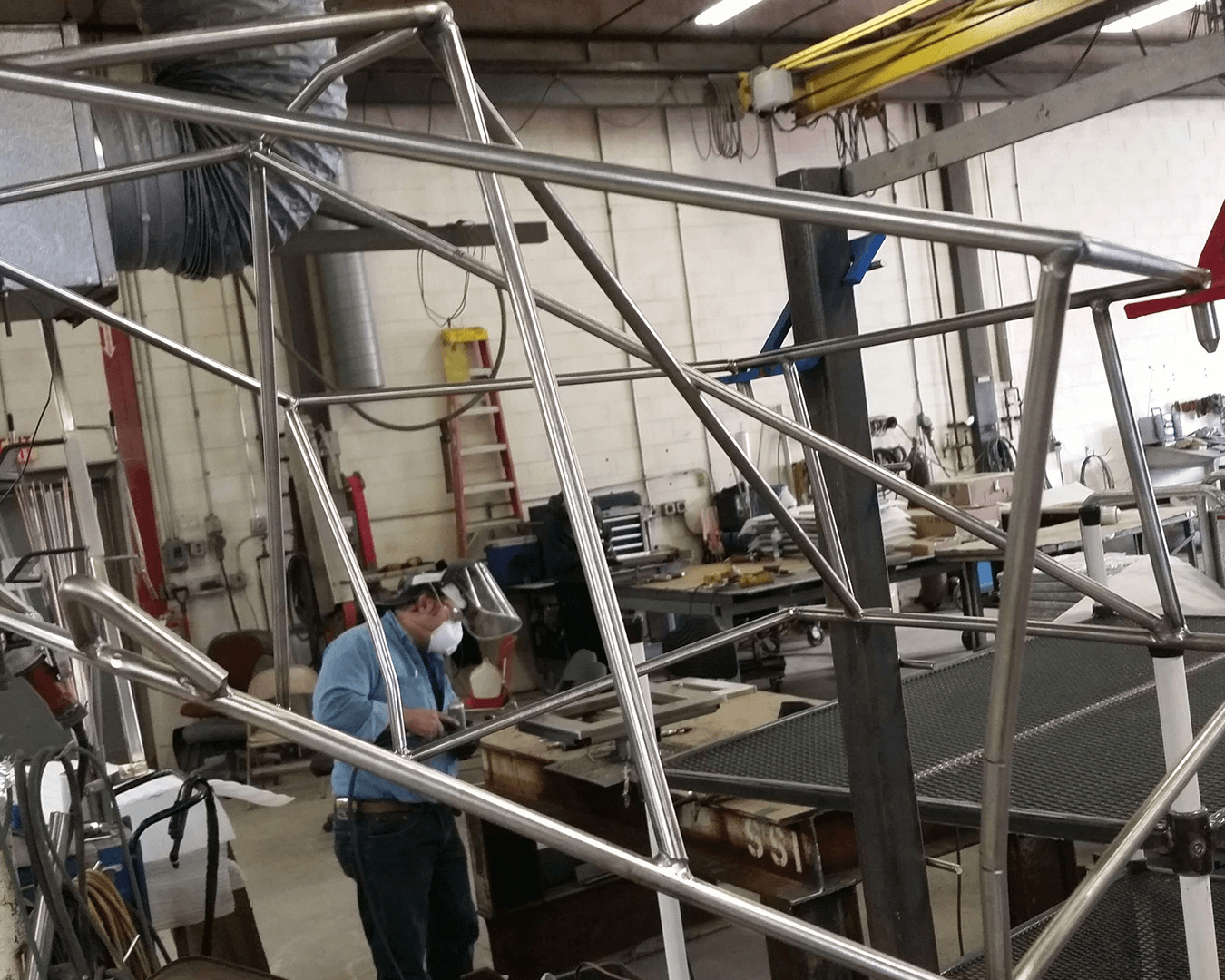

- Stainless steel TIG welding by well trained and certified welders

- Mask incorporation for guarding No Paint zones

- Efficient operator loading ergonomics

- Use of jigs to ensure fabrication of exact copies

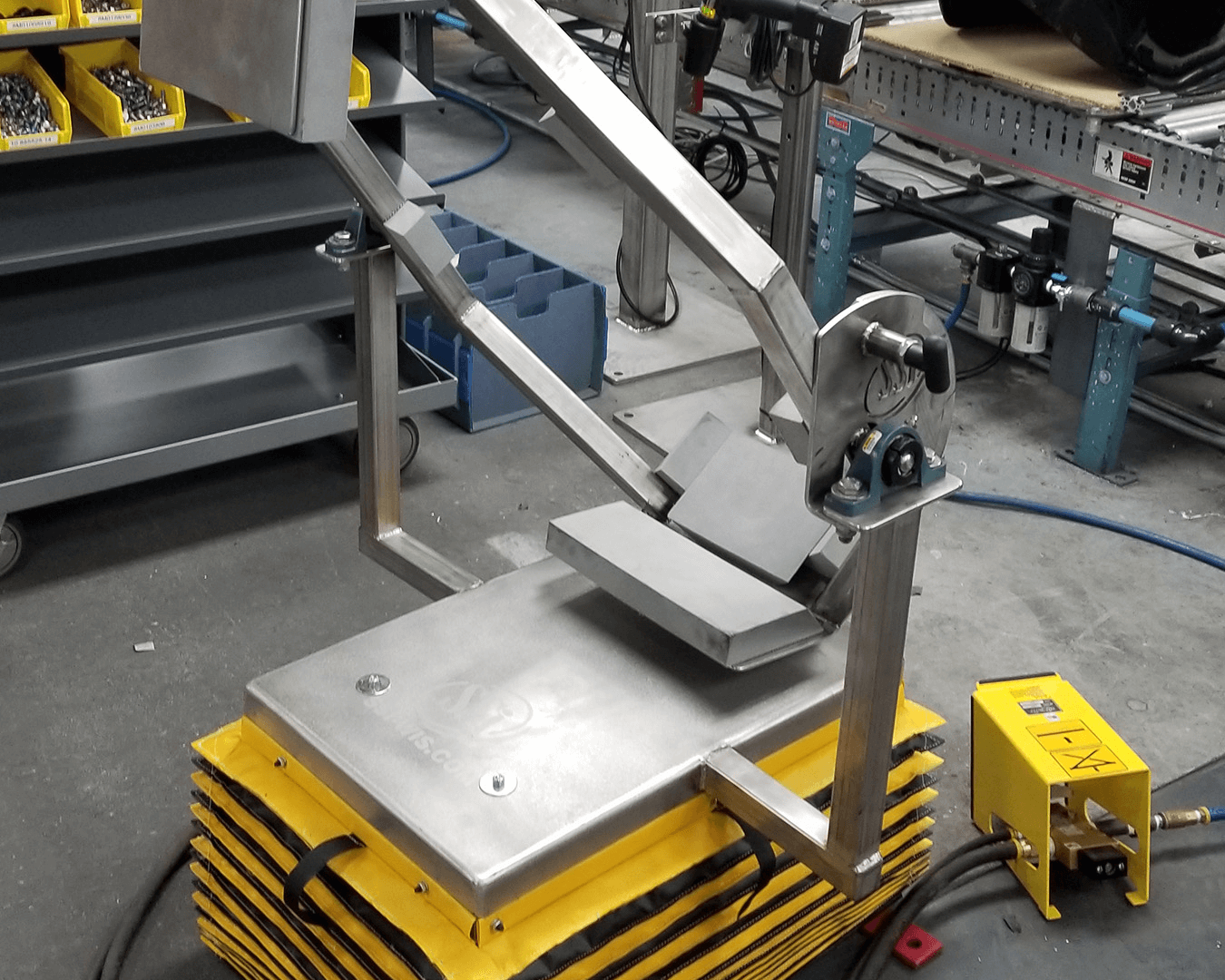

Paint Line Conveyor System

- Re-work existing conveyors to accommodate the ever-changing needs of painting facilities

- Fabrication of new paint conveyor systems

- Grounding system design and installation

- Chain conveyors with custom carts to fit your applications

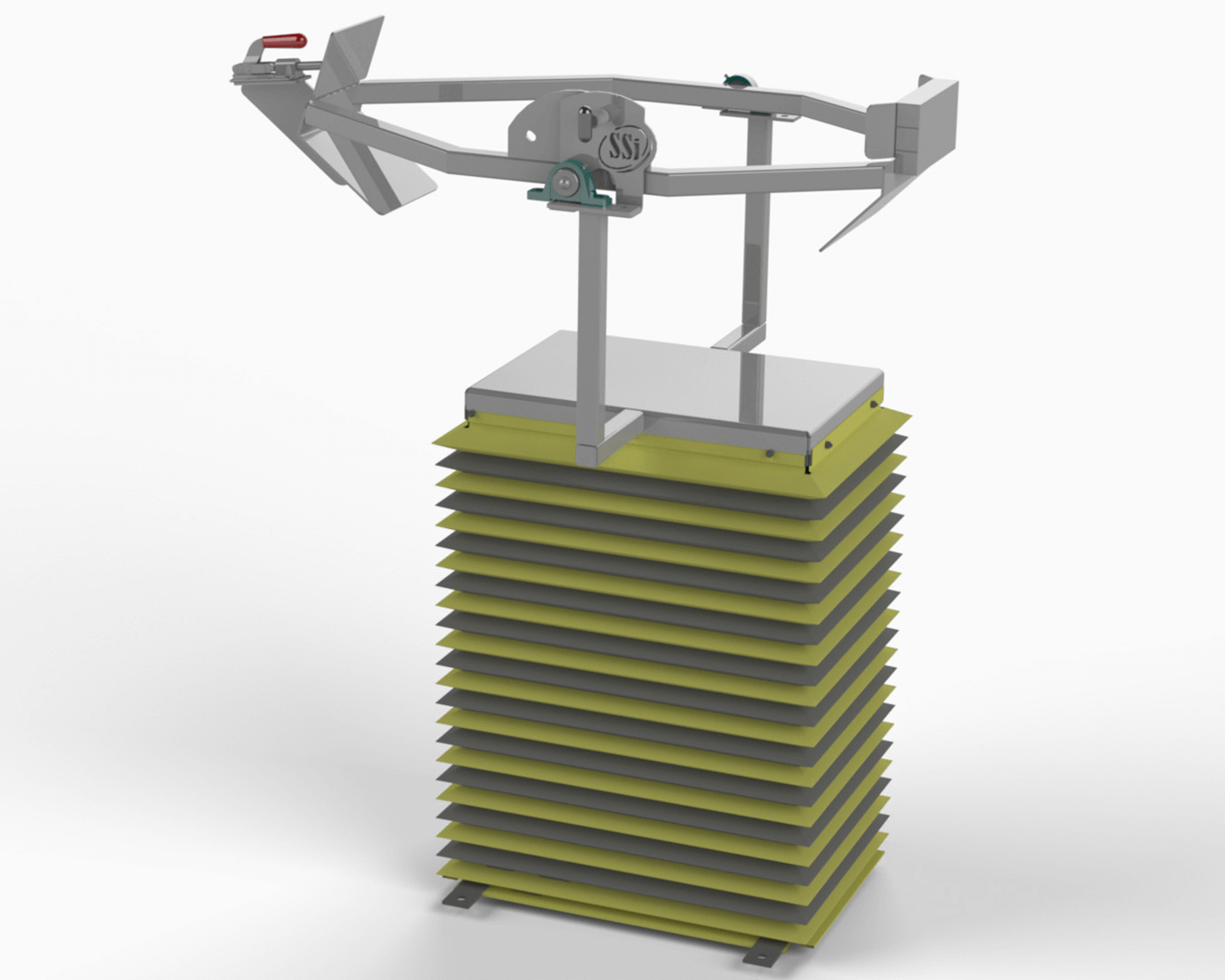

- Mechanical part rotating and locking devices for orienting parts in proper directions

Spray Booth Fabrication & Installation

- Modify existing spray booths during plant shut down

- Fabricate new spray booth and required entrance and exits

- Booth airflow design and installation

- Installation of IR oven assemblies

- Spray booth preventative maintenance and service

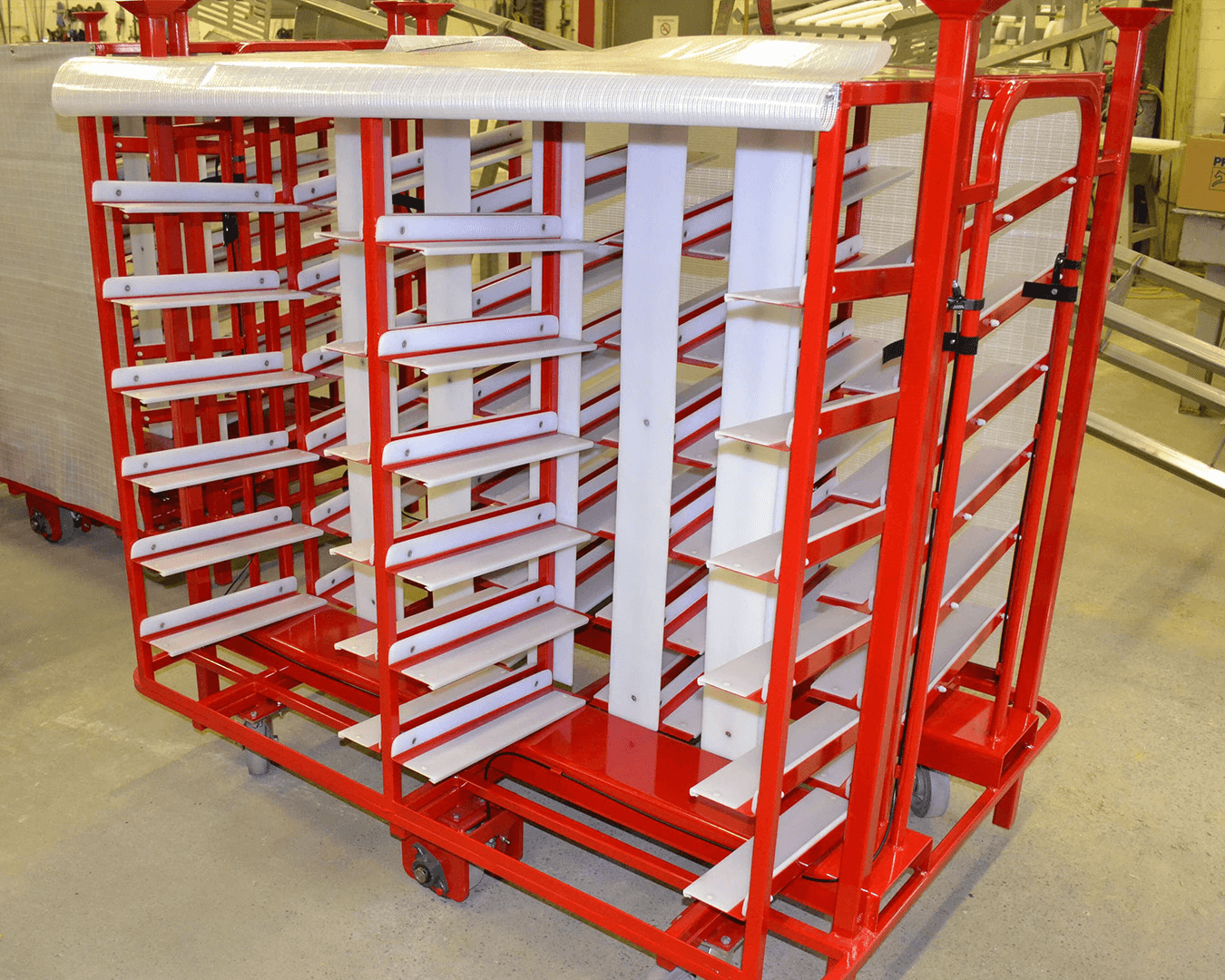

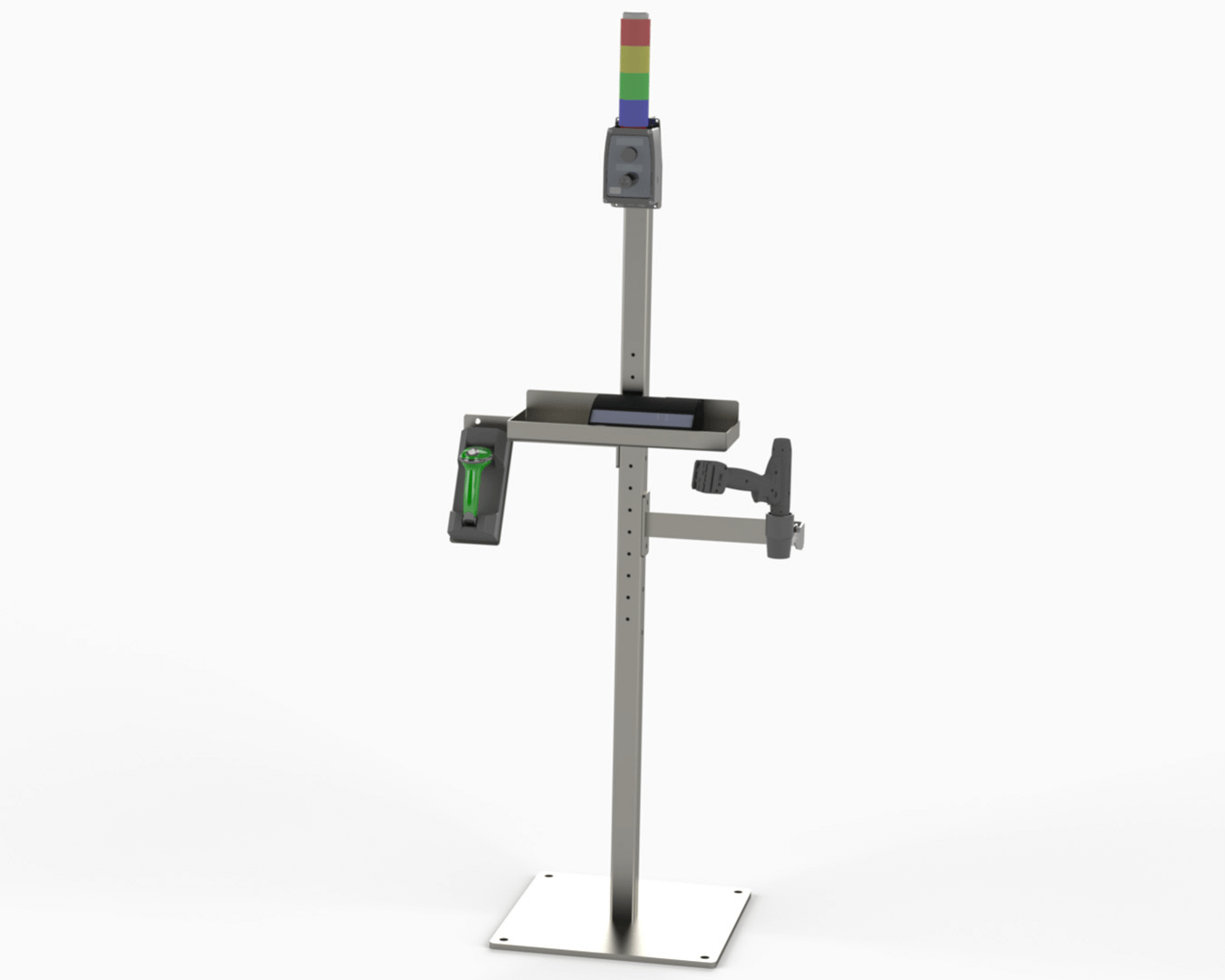

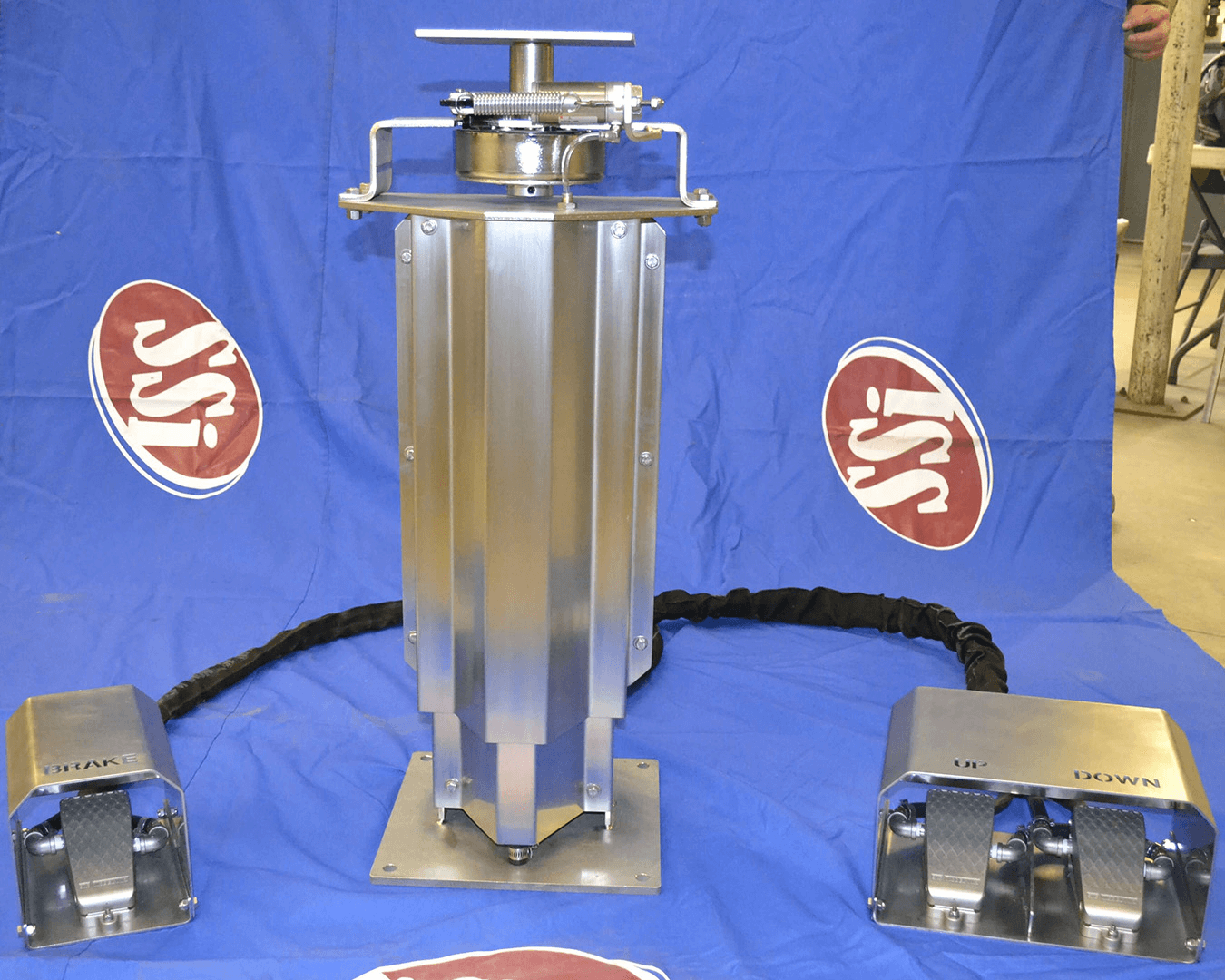

Buffing Stations & Part Handling Equipment

- Detail/Buffing station design, fabrication, and installation

- Ergonomically sound, paint storage carts for finished products

- Assembly stations for ergonomically maneuvering and assembling parts

- Custom tool stations for organizing parts, tools, and equipment