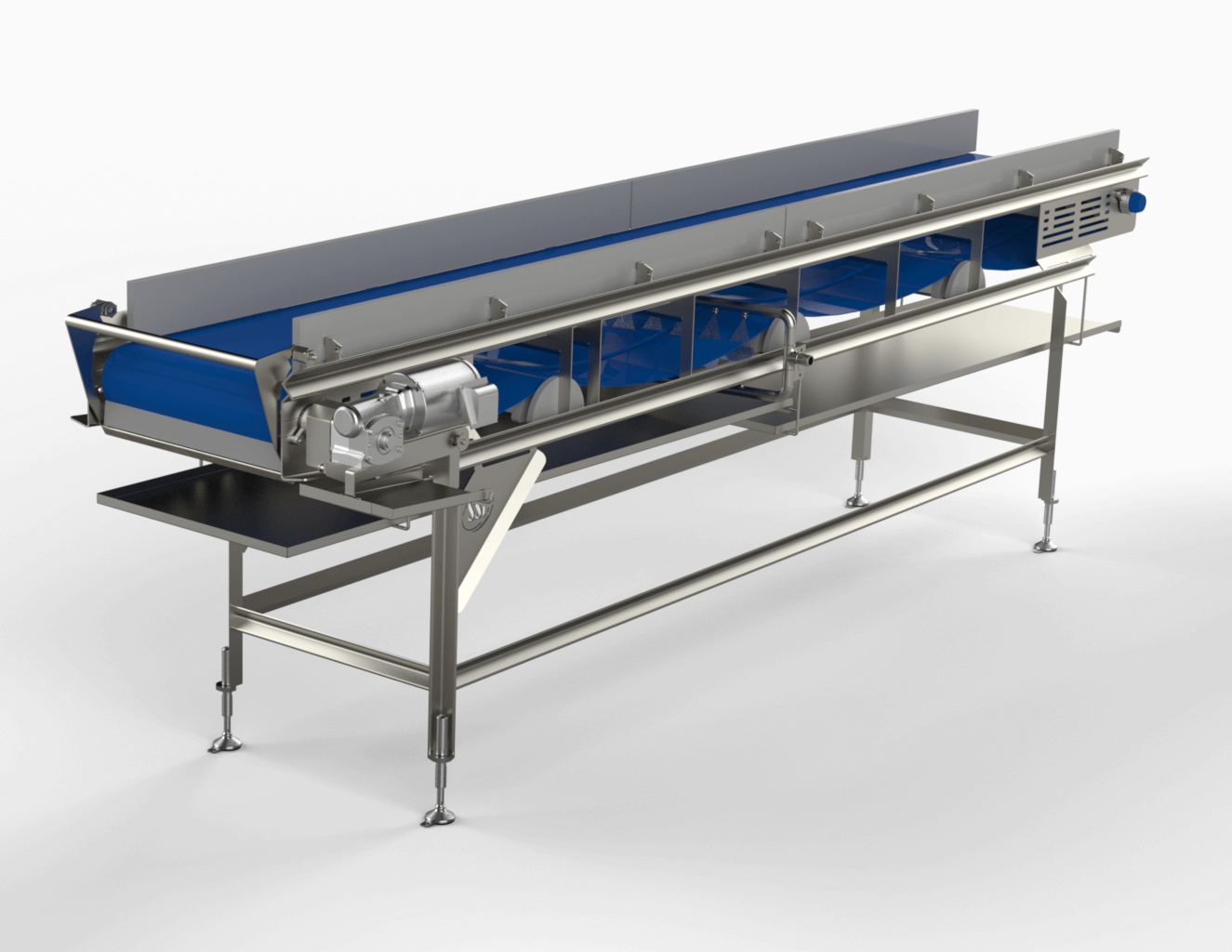

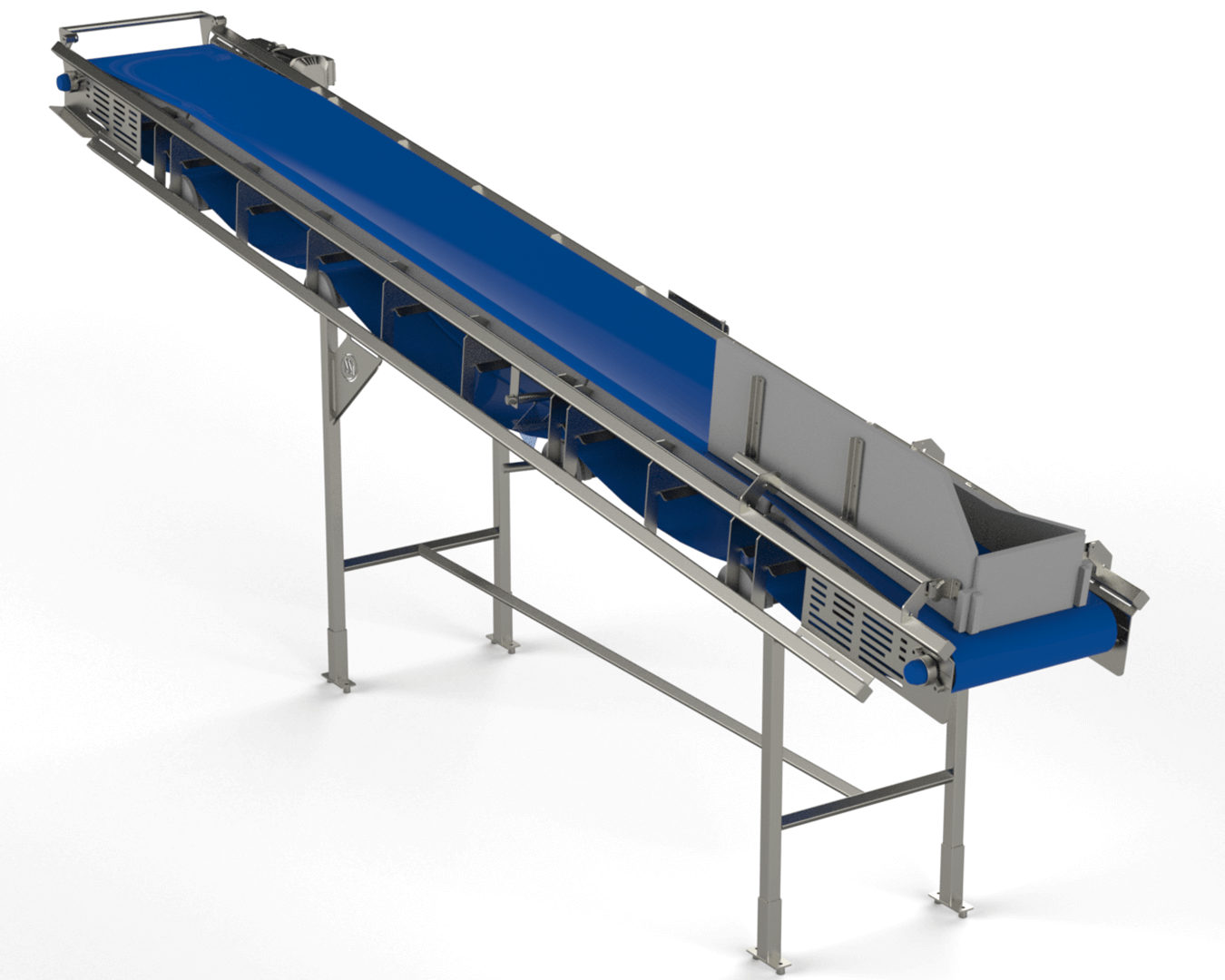

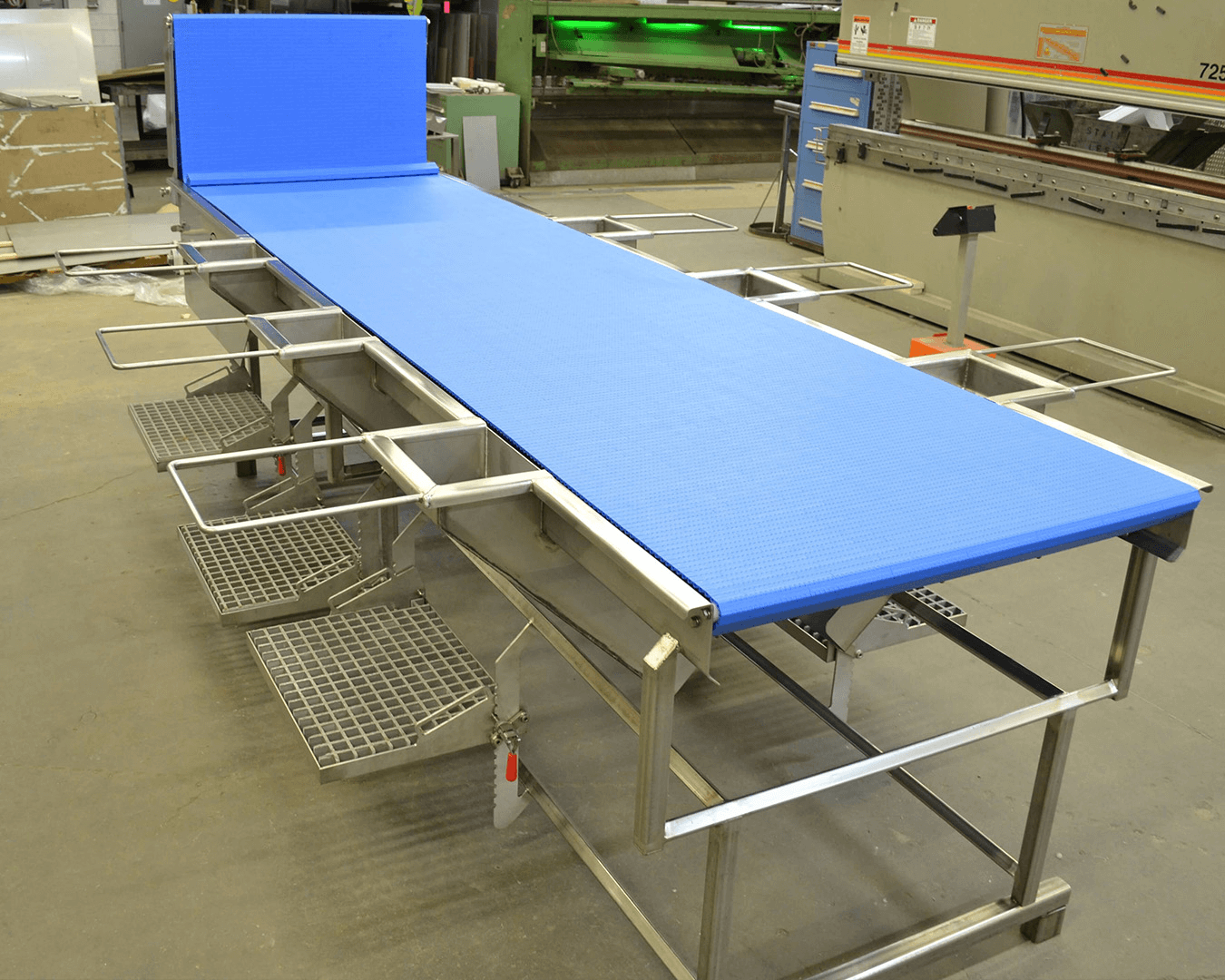

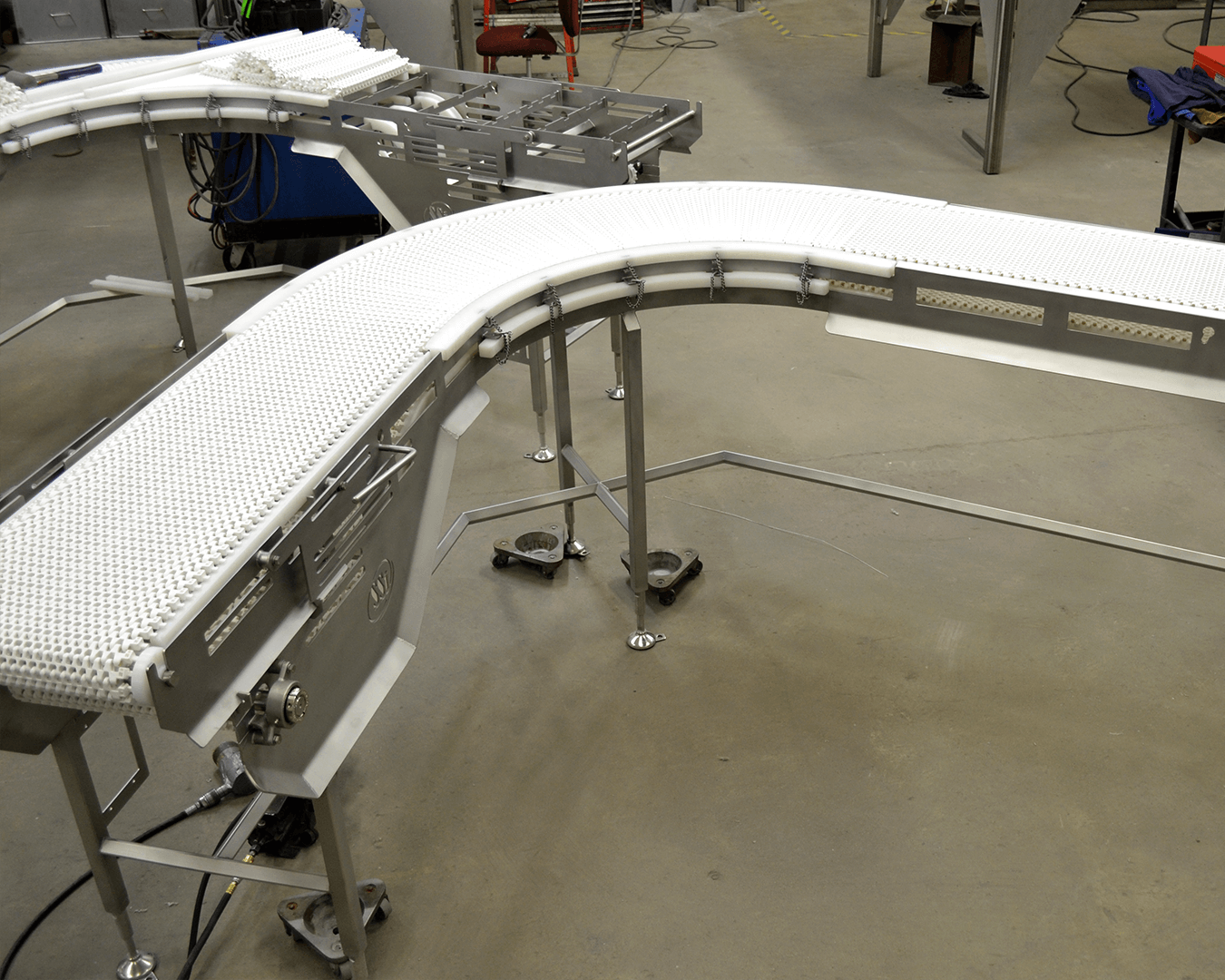

Sanitary Conveyors

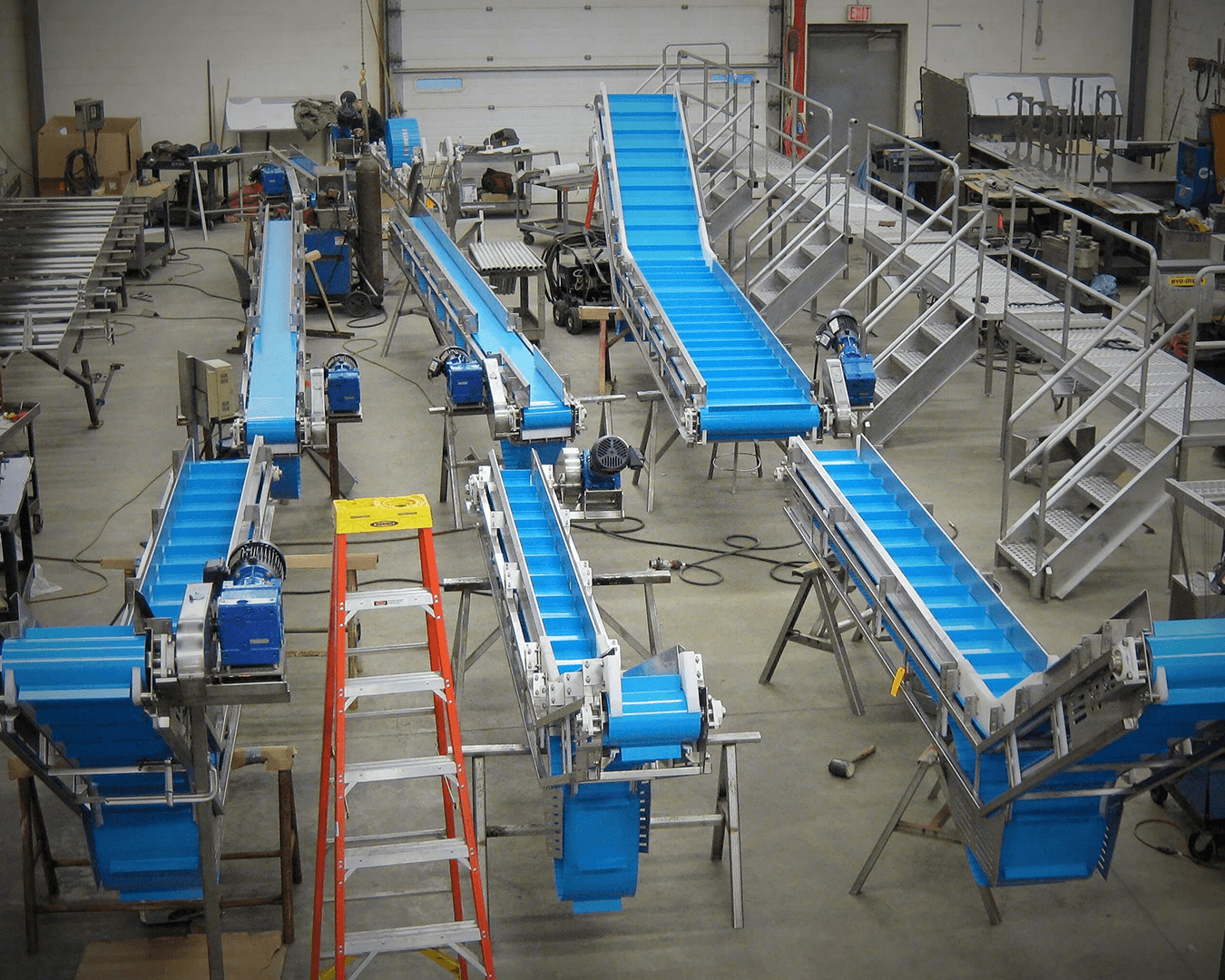

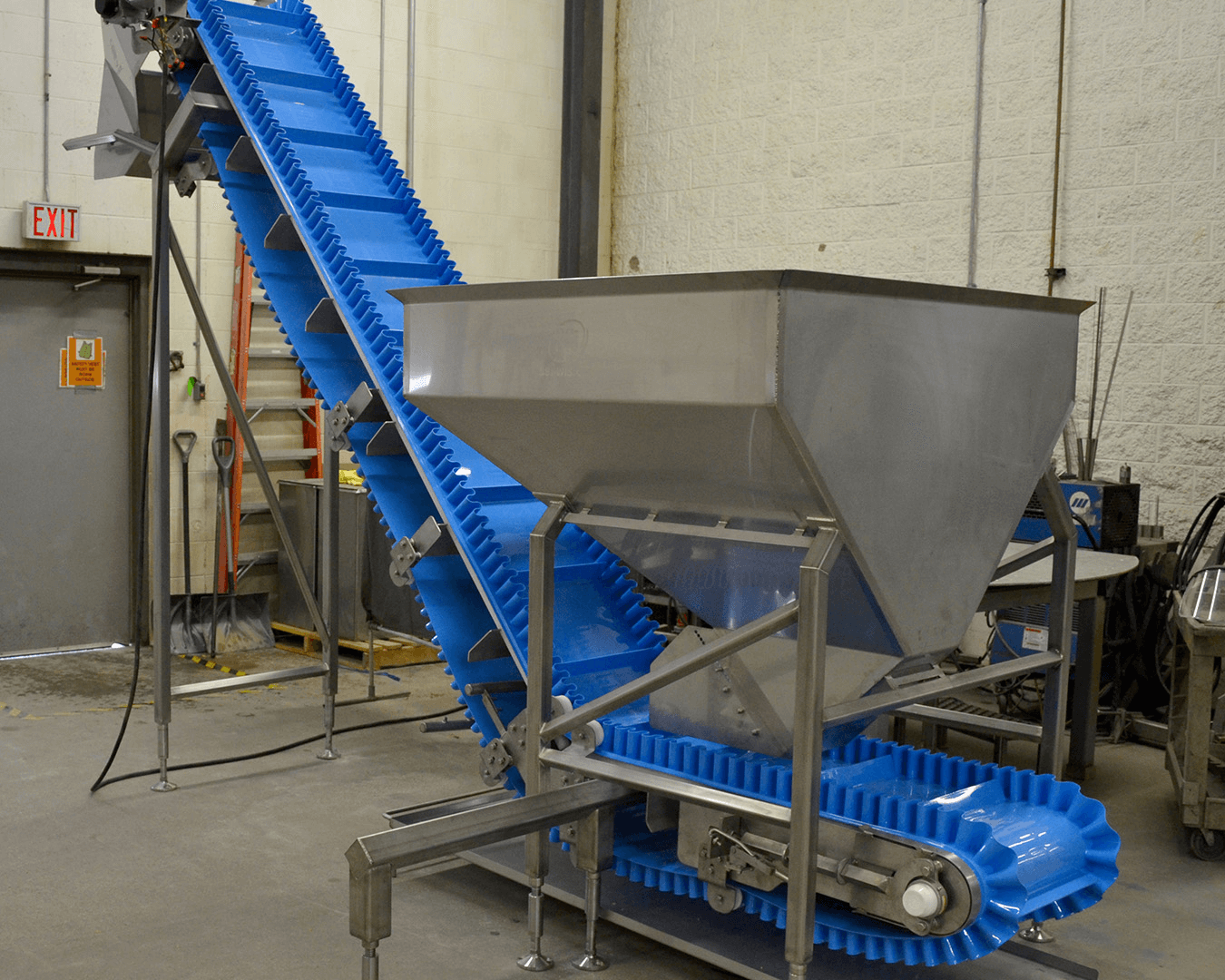

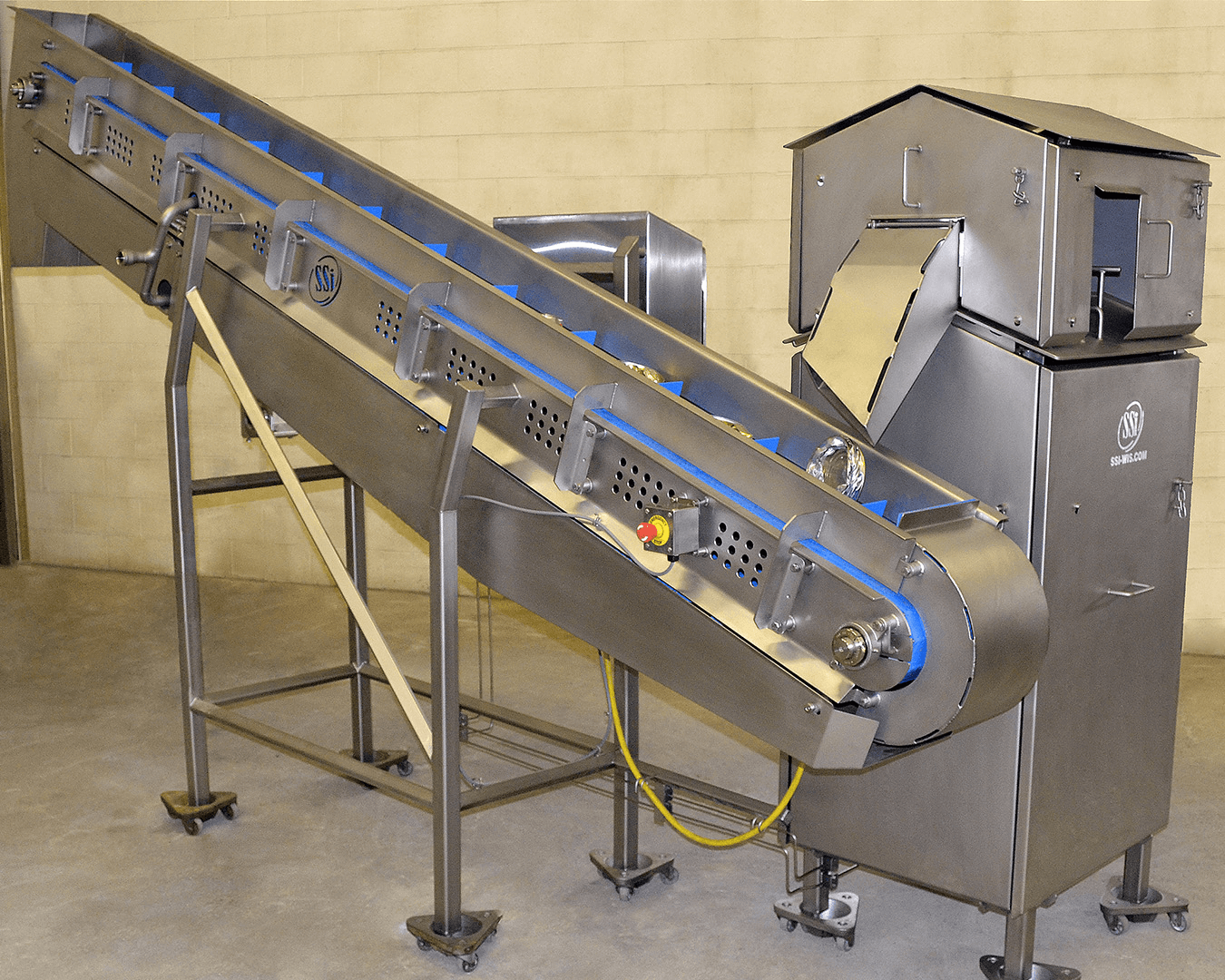

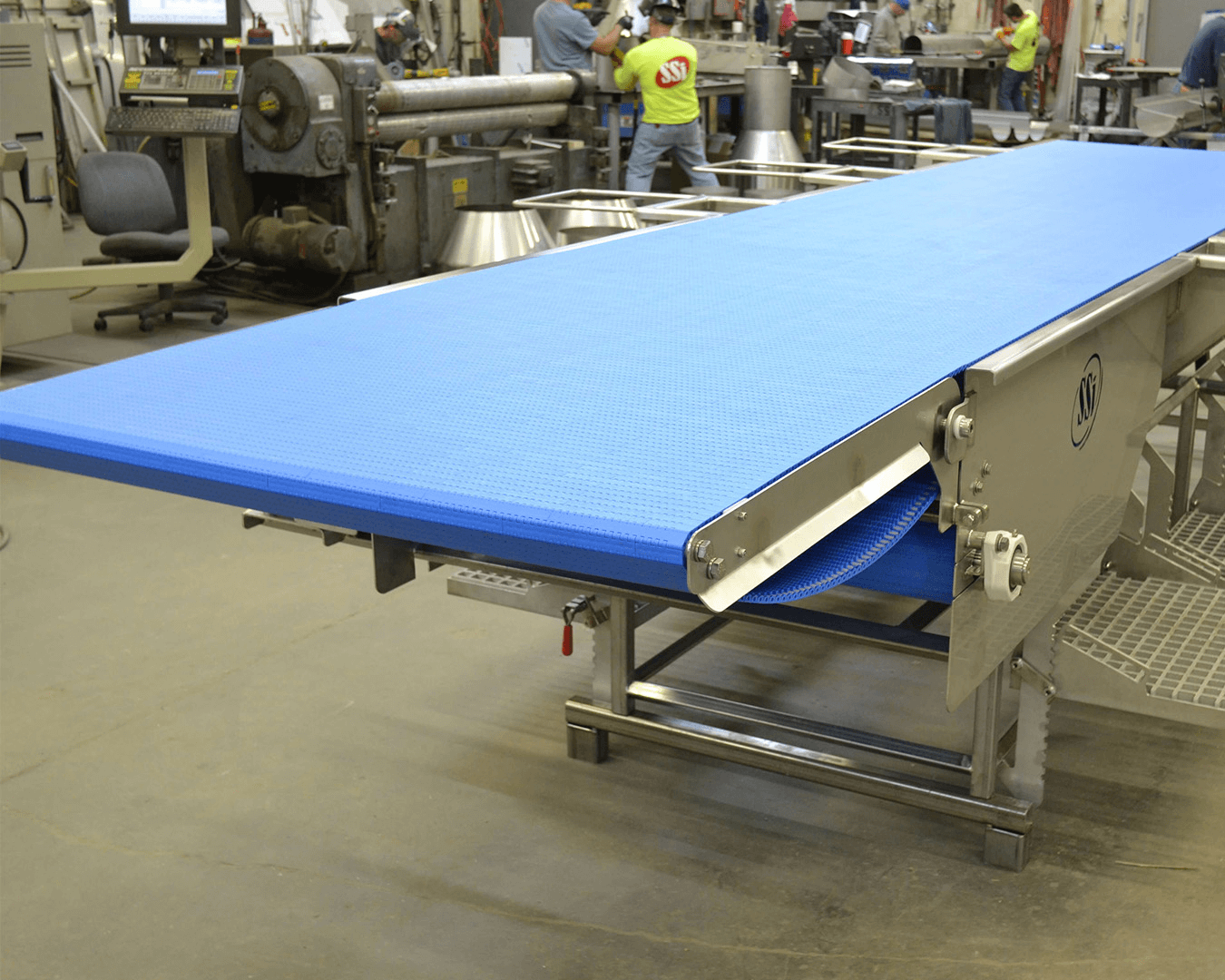

From spiral to alpine to product sorting and orienting, SSi has experience in handling all types of difficult products. We have had experience in the food processing/manufacturing industry for 32 years! Our specialty is custom conveyor equipment for food and packaging areas in various types of facilities.

Sanitary designed equipment is what we excel in because we know, from experience, what is acceptable to abide by FDA/USDA and individual plant standards. We work closely with the customer to develop a conveyor from as basic as the conceptual stage to designing full line layouts in-house. SSi is your one source solution provider!

A major benefit to using SSi for your conveyor fabrication and installation is speed. Typically for a straight forward custom conveyor the lead time falls between 4-6 weeks. Every project is different in the custom equipment world, so we strive to work closely together with clients to hit the deadlines other manufacturers run away from.

Design Capabilities

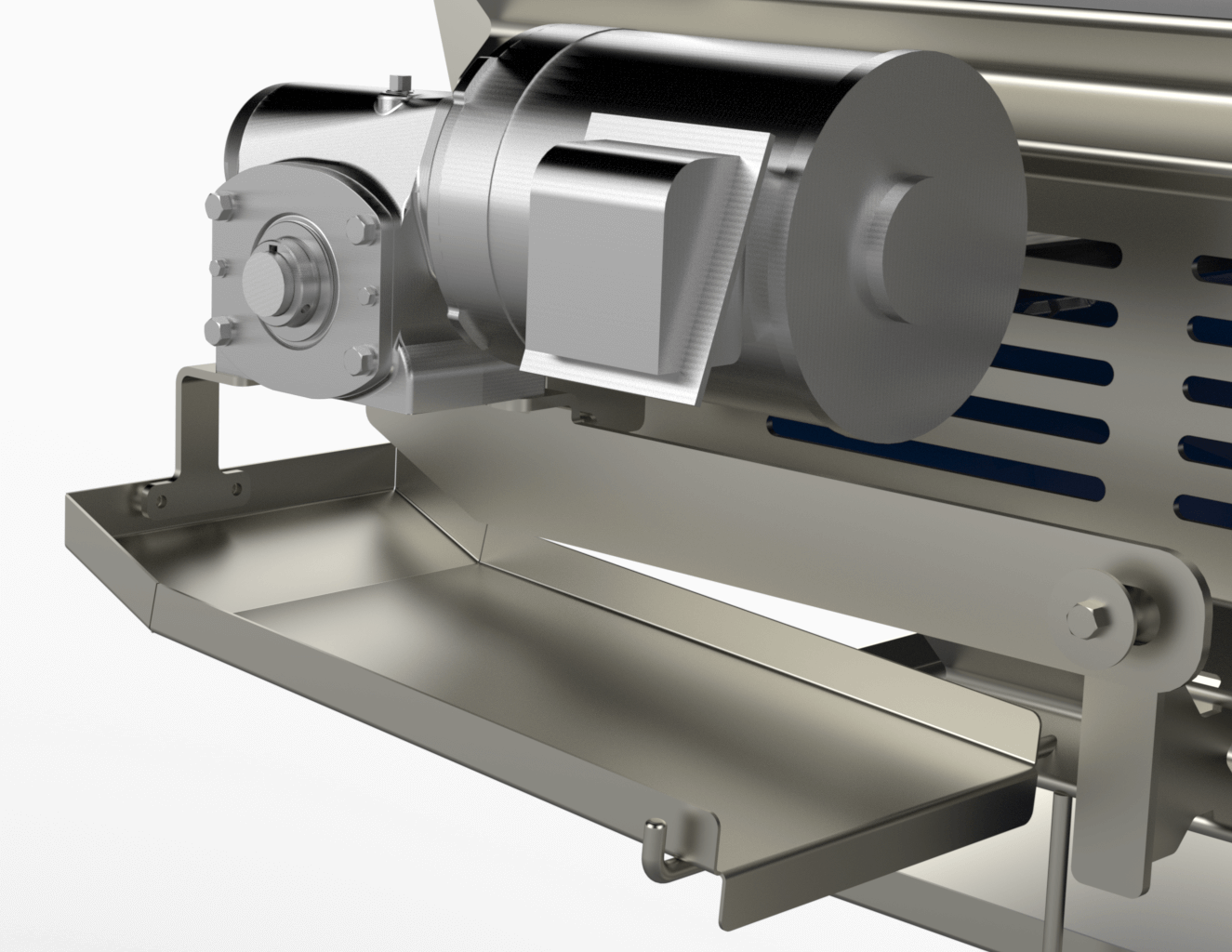

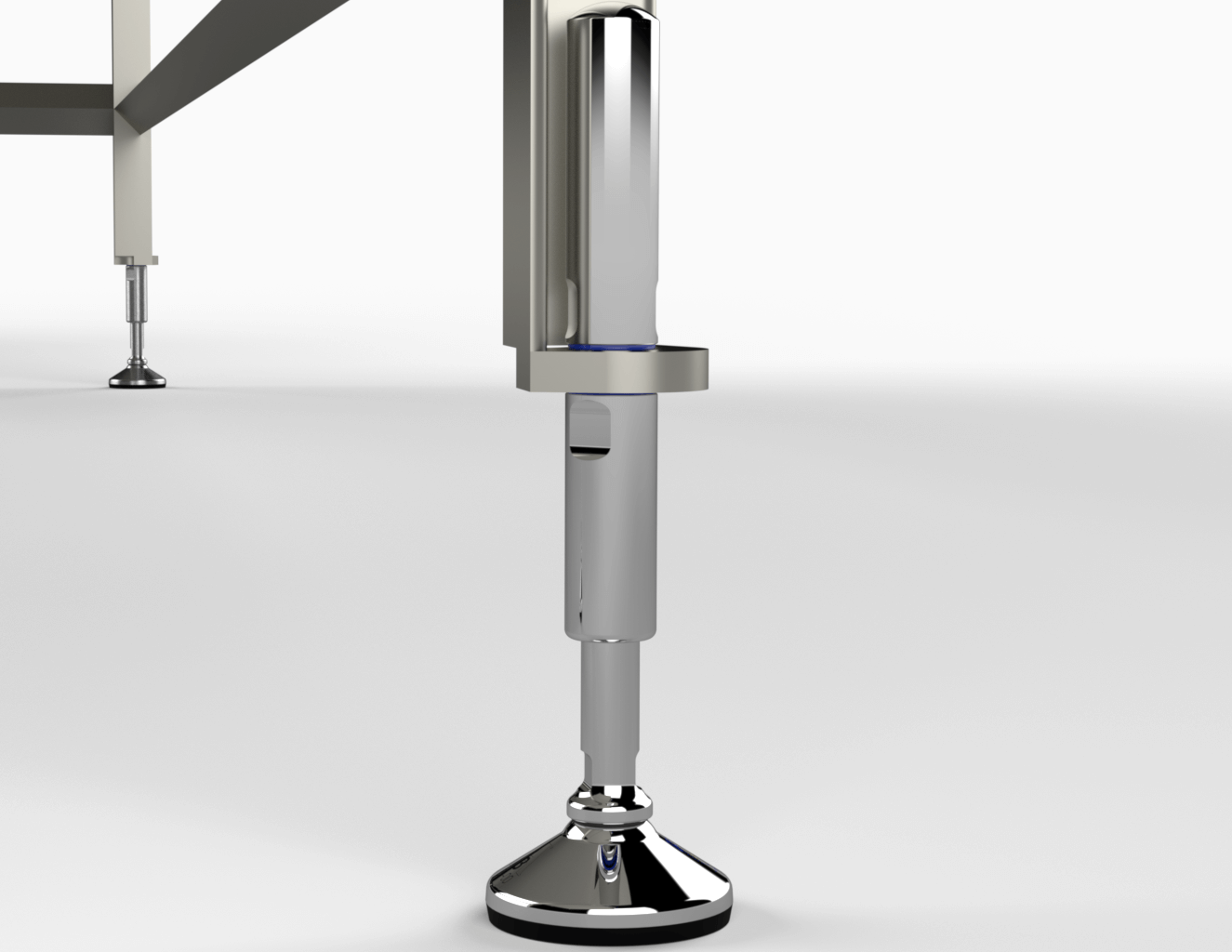

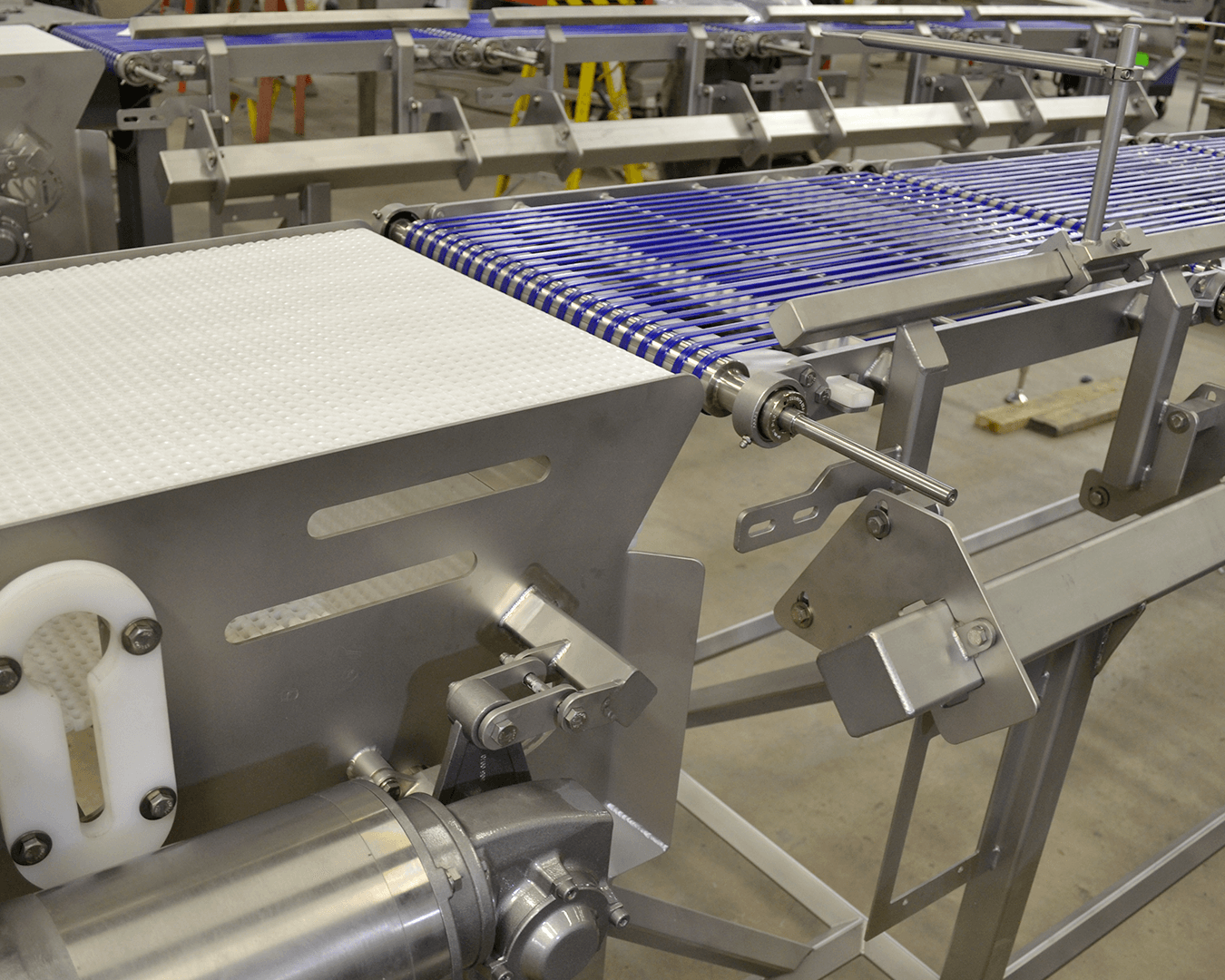

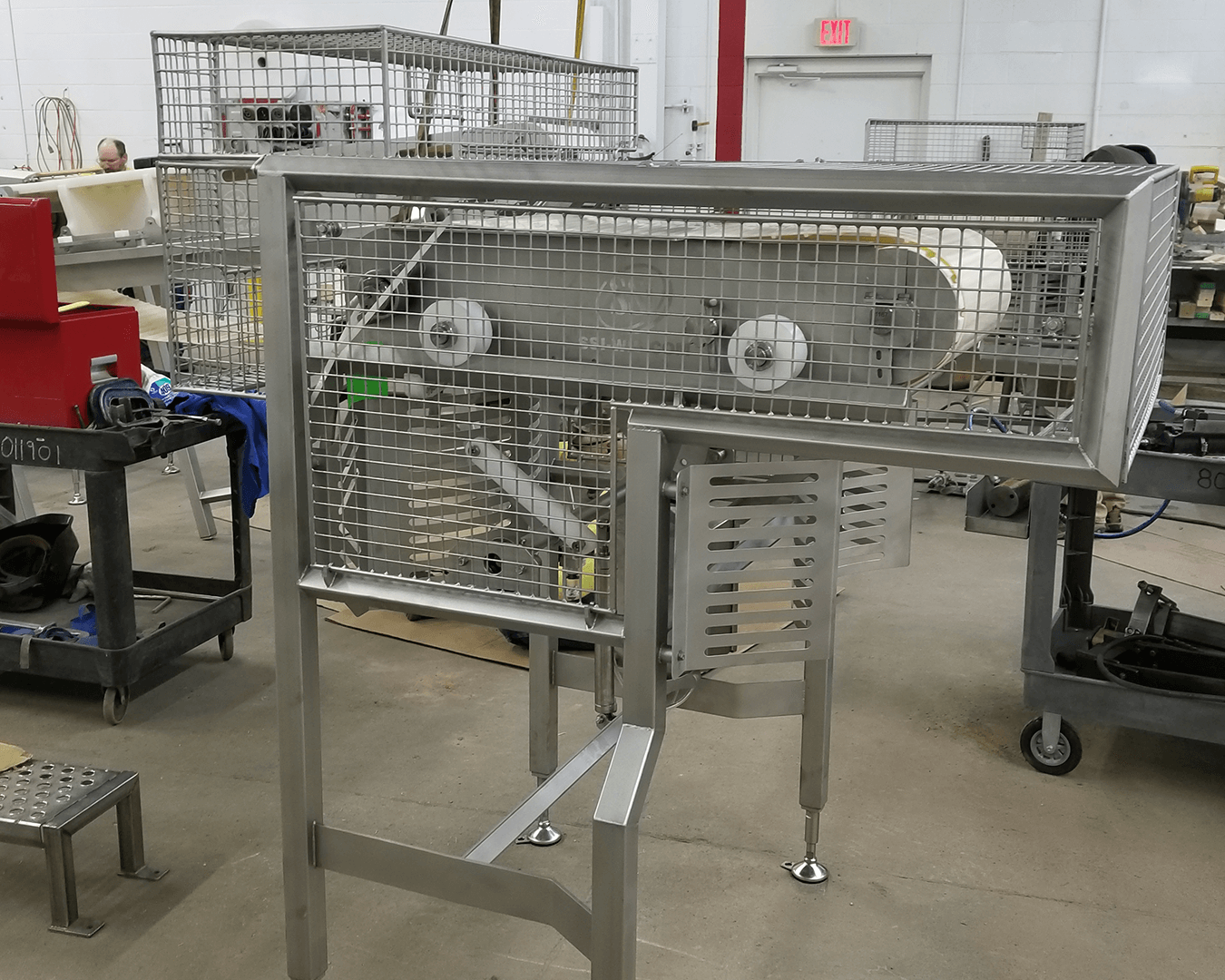

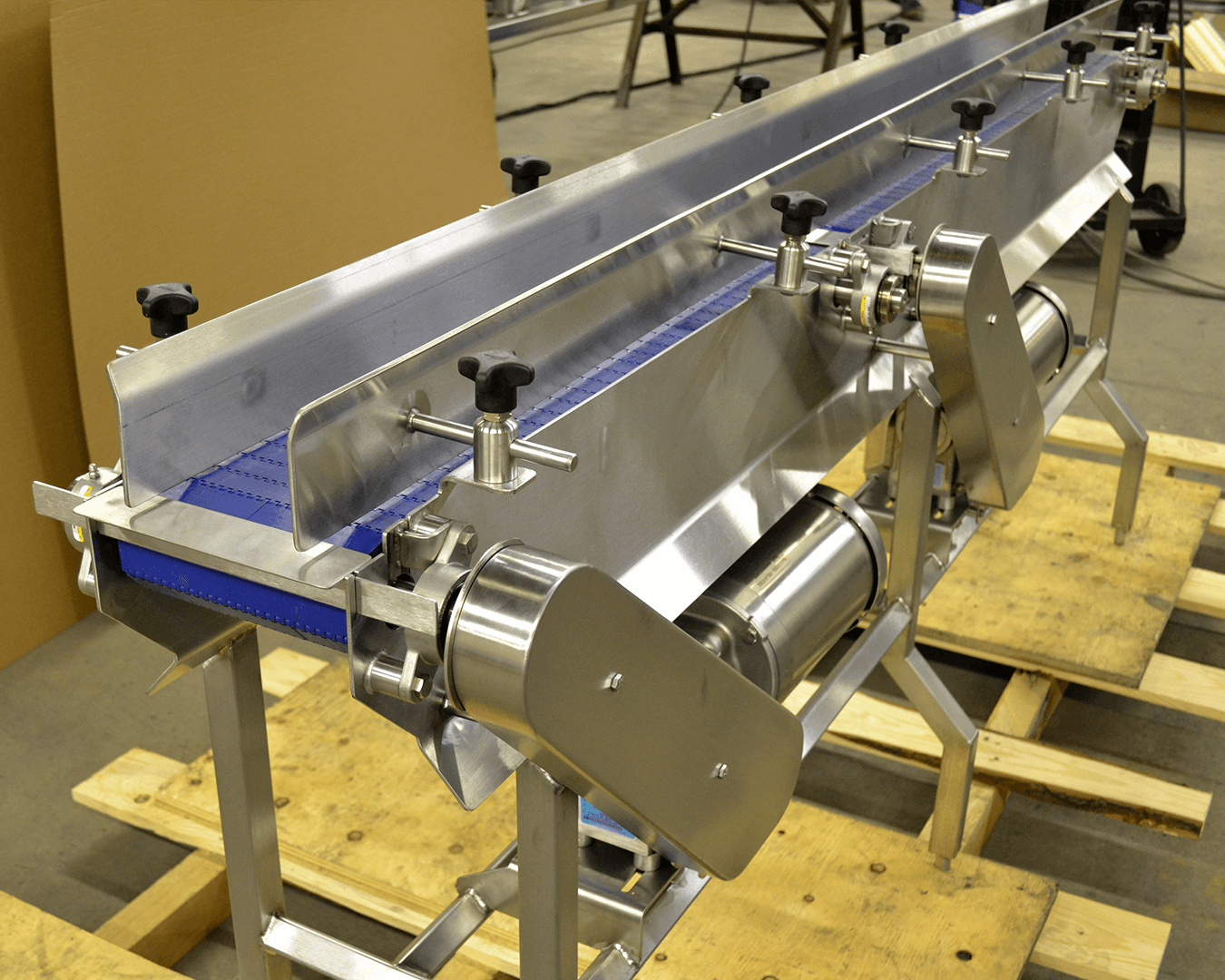

- Stand-offs for bearing and gear boxes to provide wash through capabilities

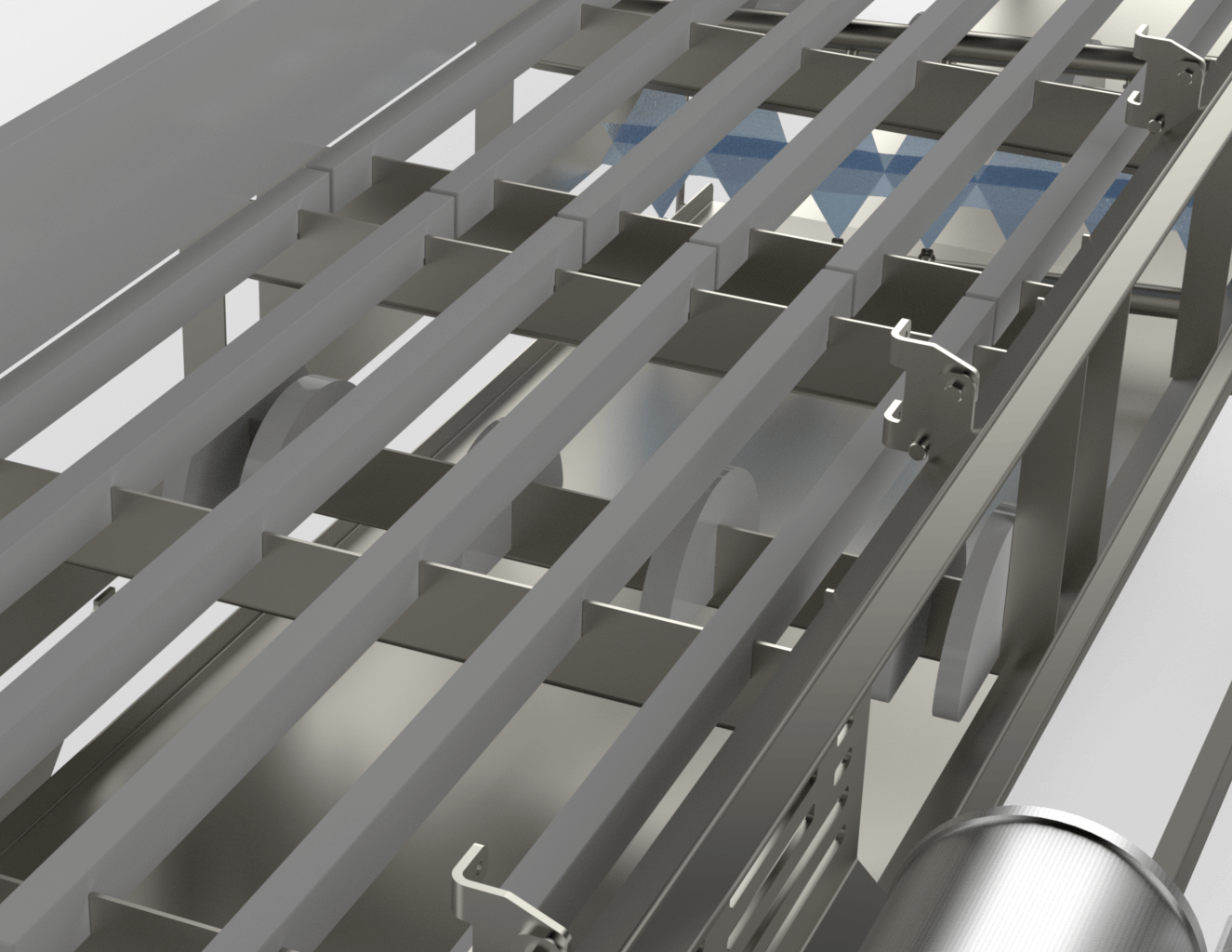

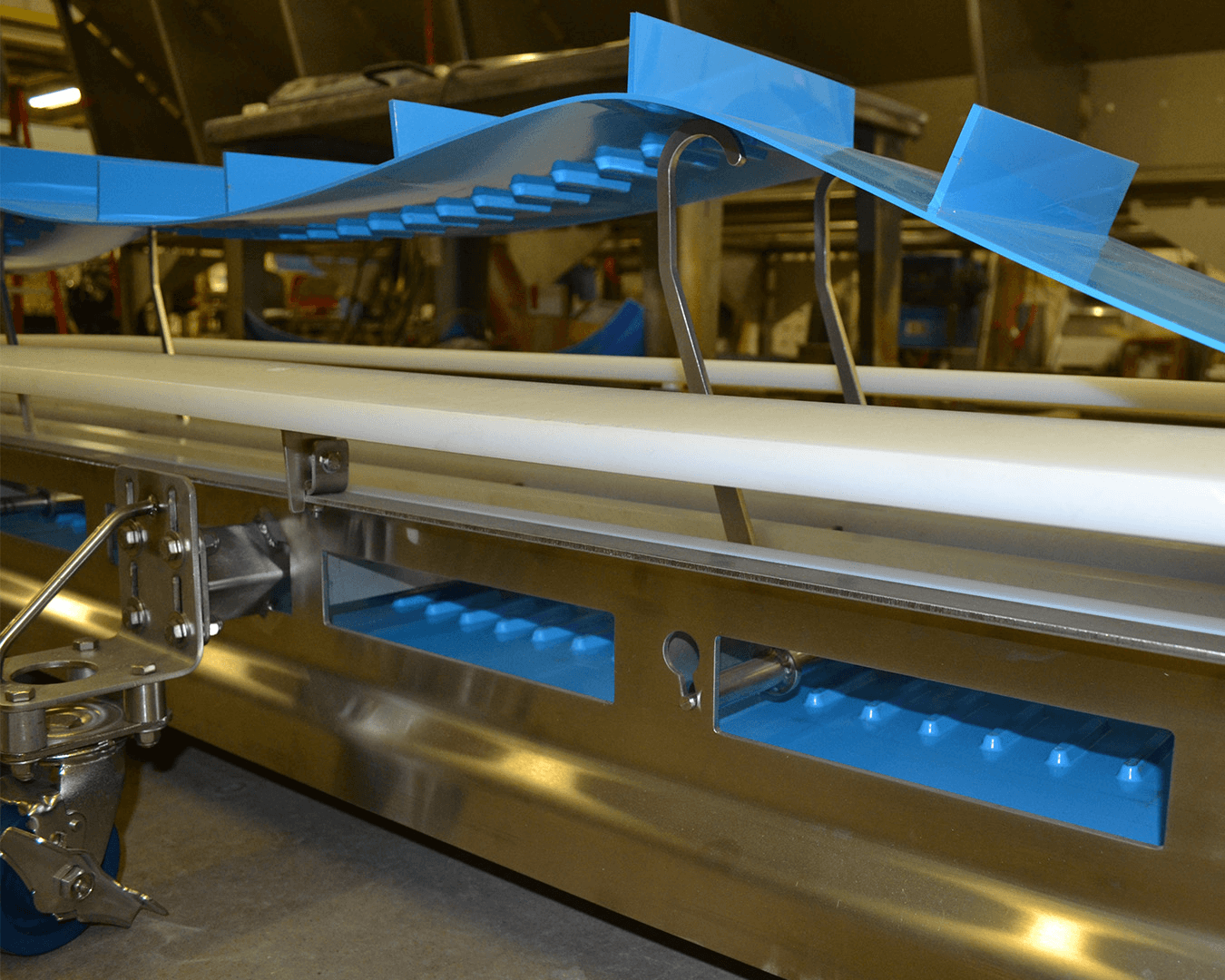

- Shaft removal cut-outs and snap ring sprocket installation for improved maintenance effectiveness and clean-ability providing reliable, trouble-free service

- Manual and automated gates, product lanes, and chutes

- Several wash through frame designs to select from

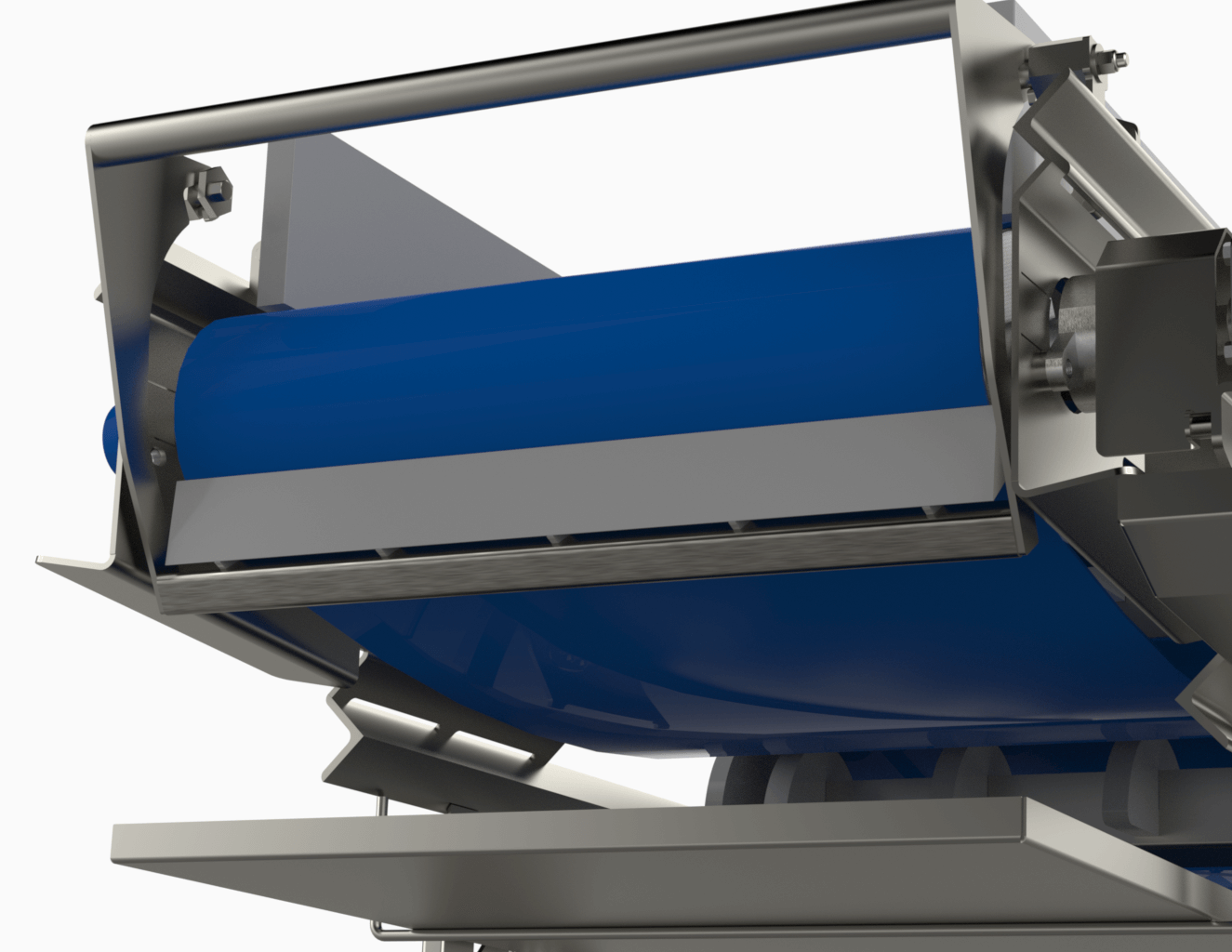

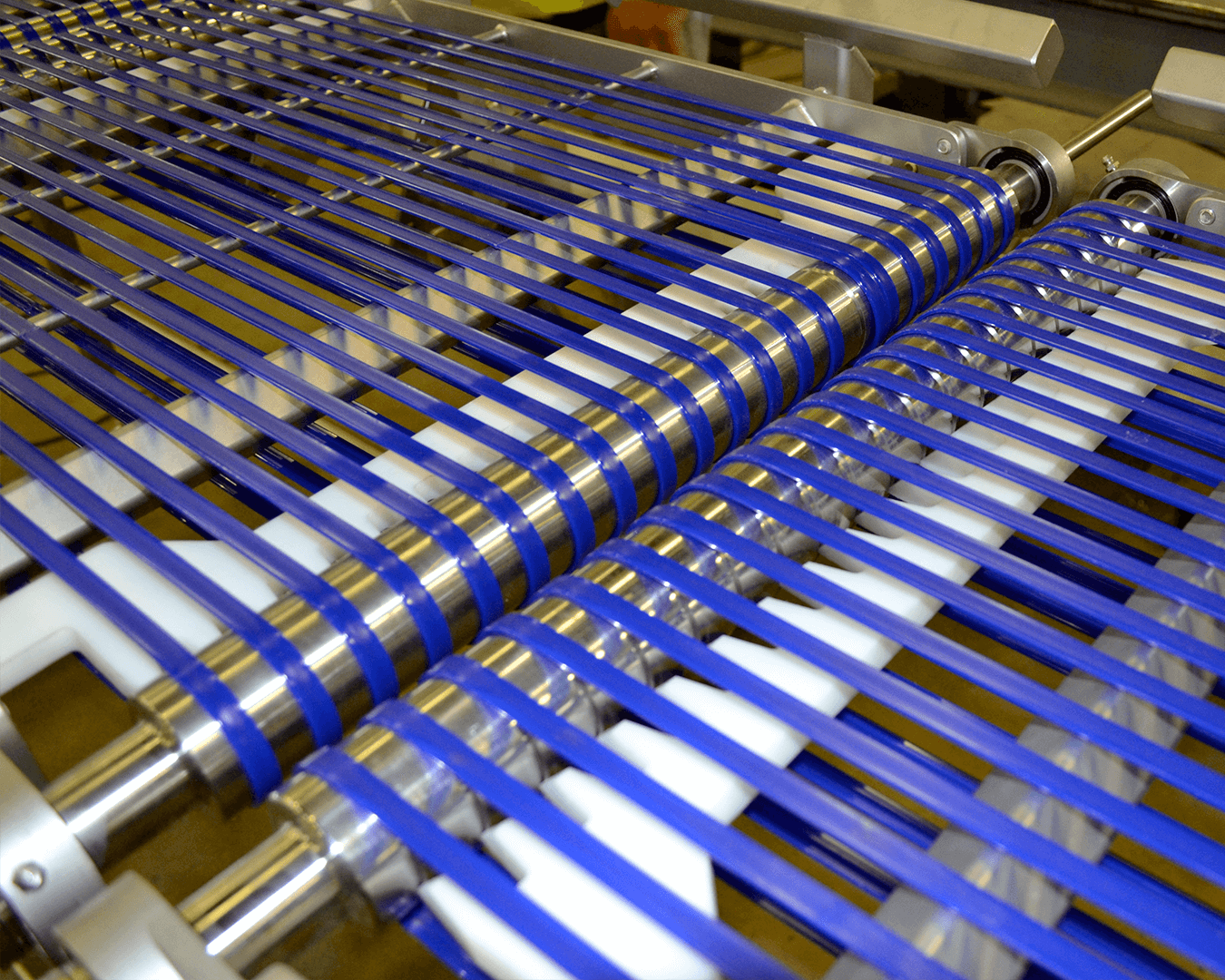

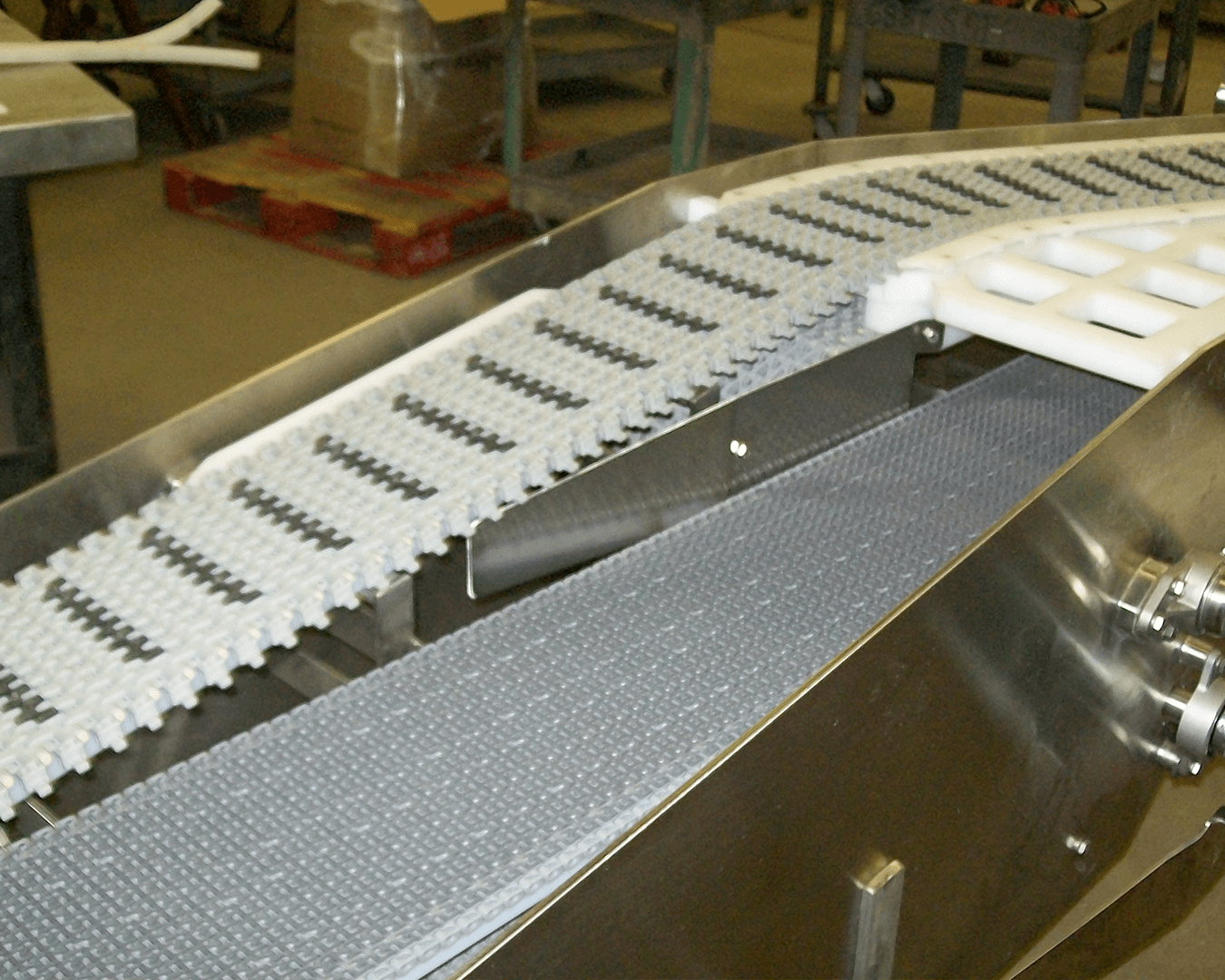

- Belting manufacturer and style to meet the application and customer requirements

- Designs provide for managing large quantities of product using limited floor space

- Pitched members to avoid moisture pooling

- Belt widths from 3″ to 60″

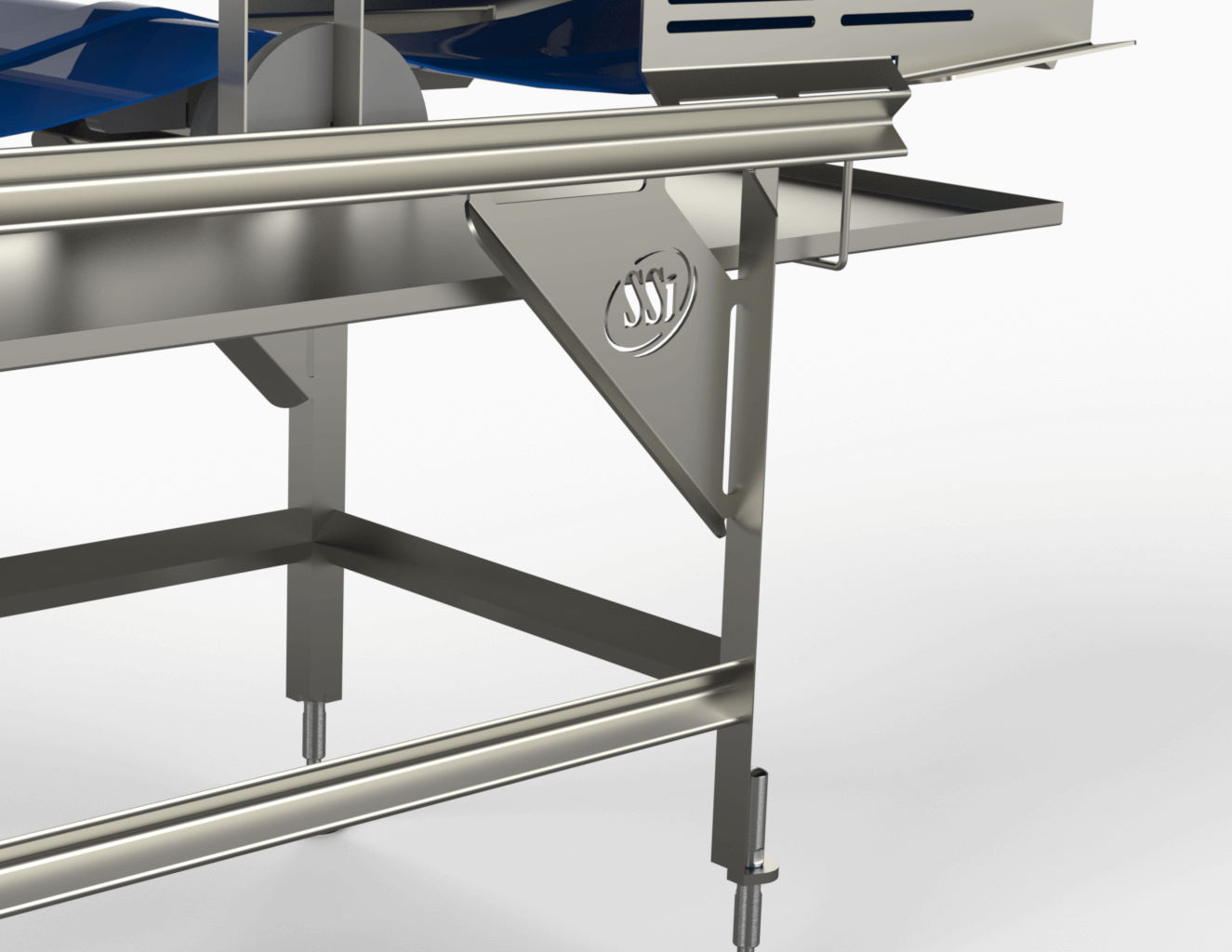

- Sanitary 3A-Dairy adjustable feet

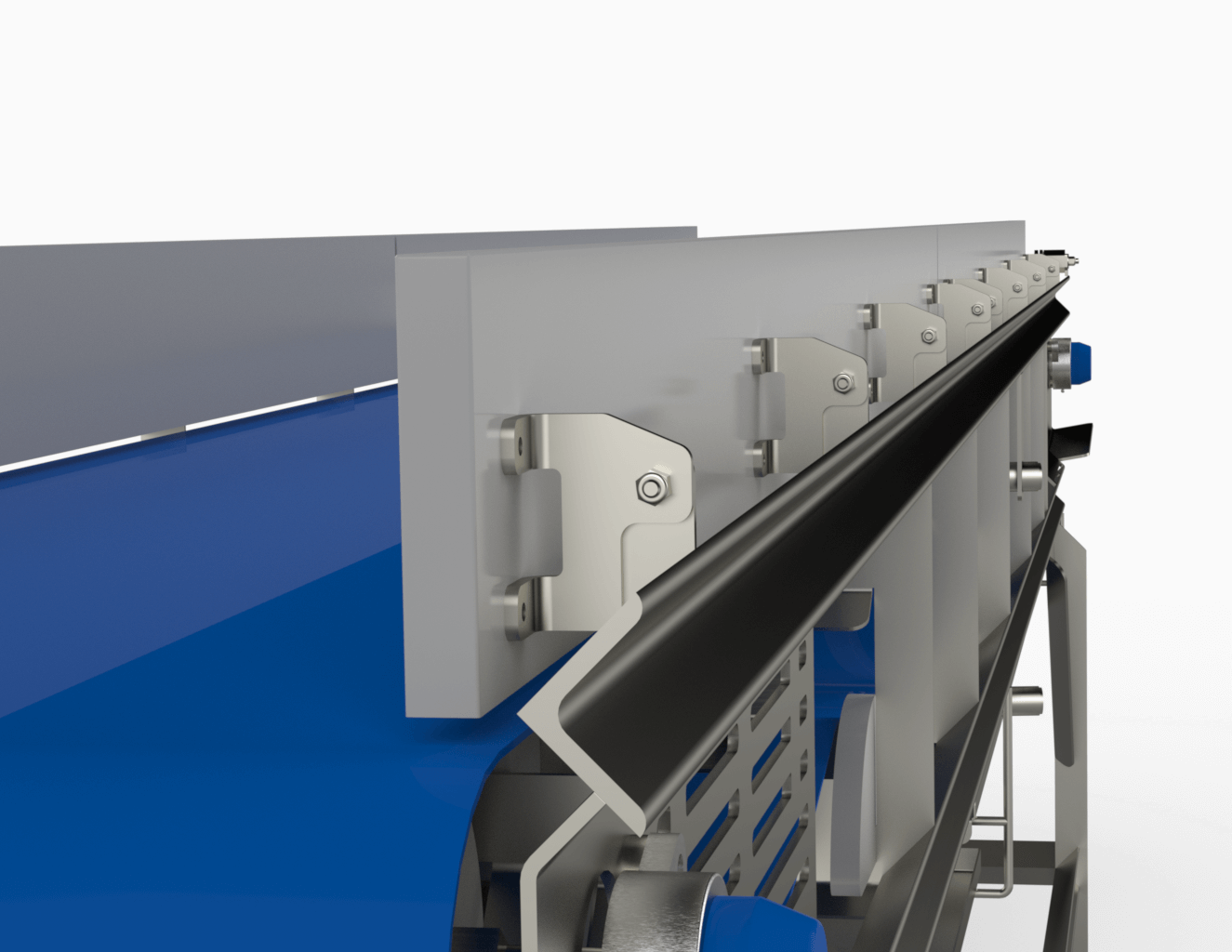

- Tool-less removable catch pans under bearings and belting

- Extremely tight radius for certain applications

- High efficiency motors

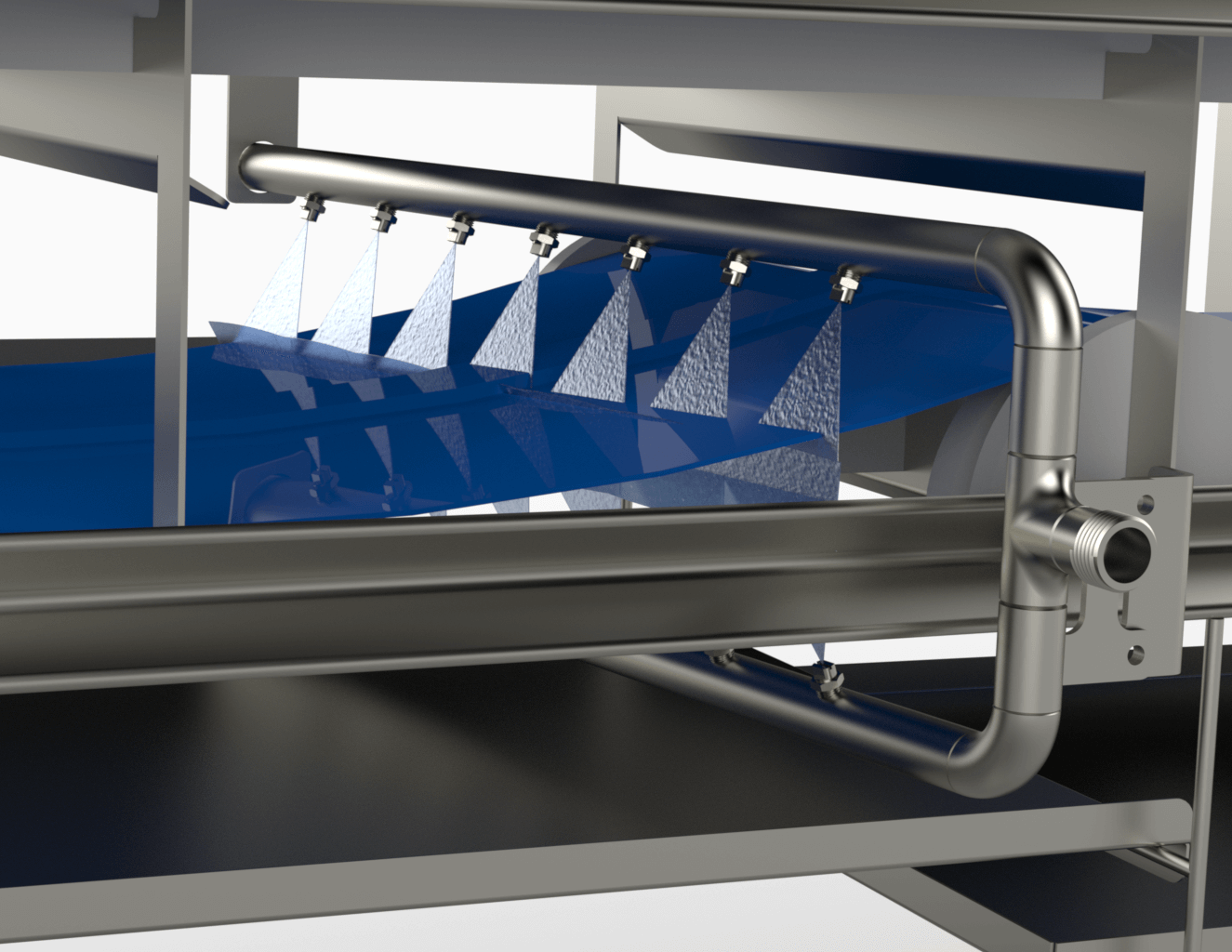

- CIP options available for rinsing, foaming, and high pressure washing (i.e. Spray Bars)

- Tool-less removable UHMW belt guides and scrapers

- Formed angle framing – No hollow members

- Tip-out & tool-less removable side rails

- Single or multiple belts on a single frame