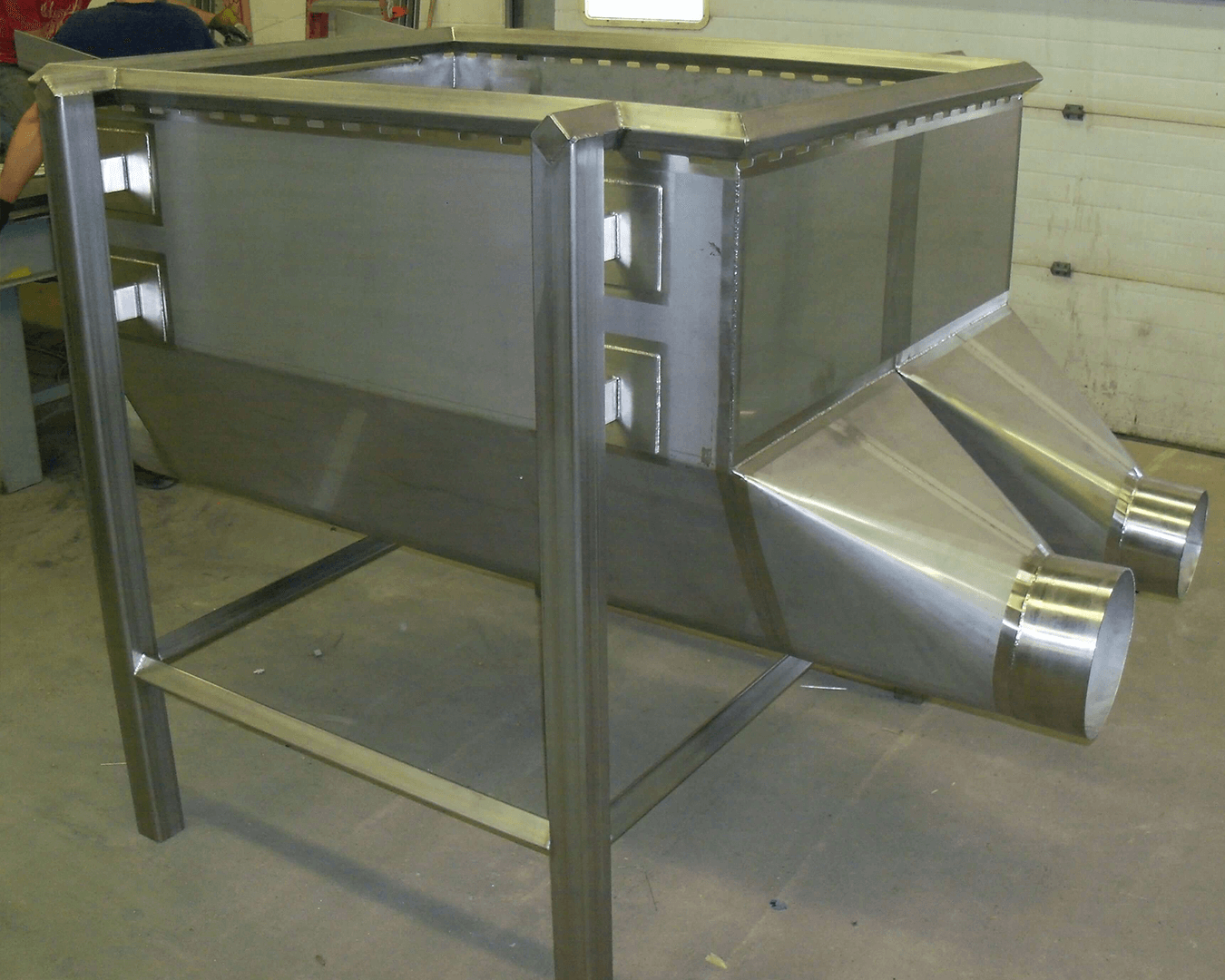

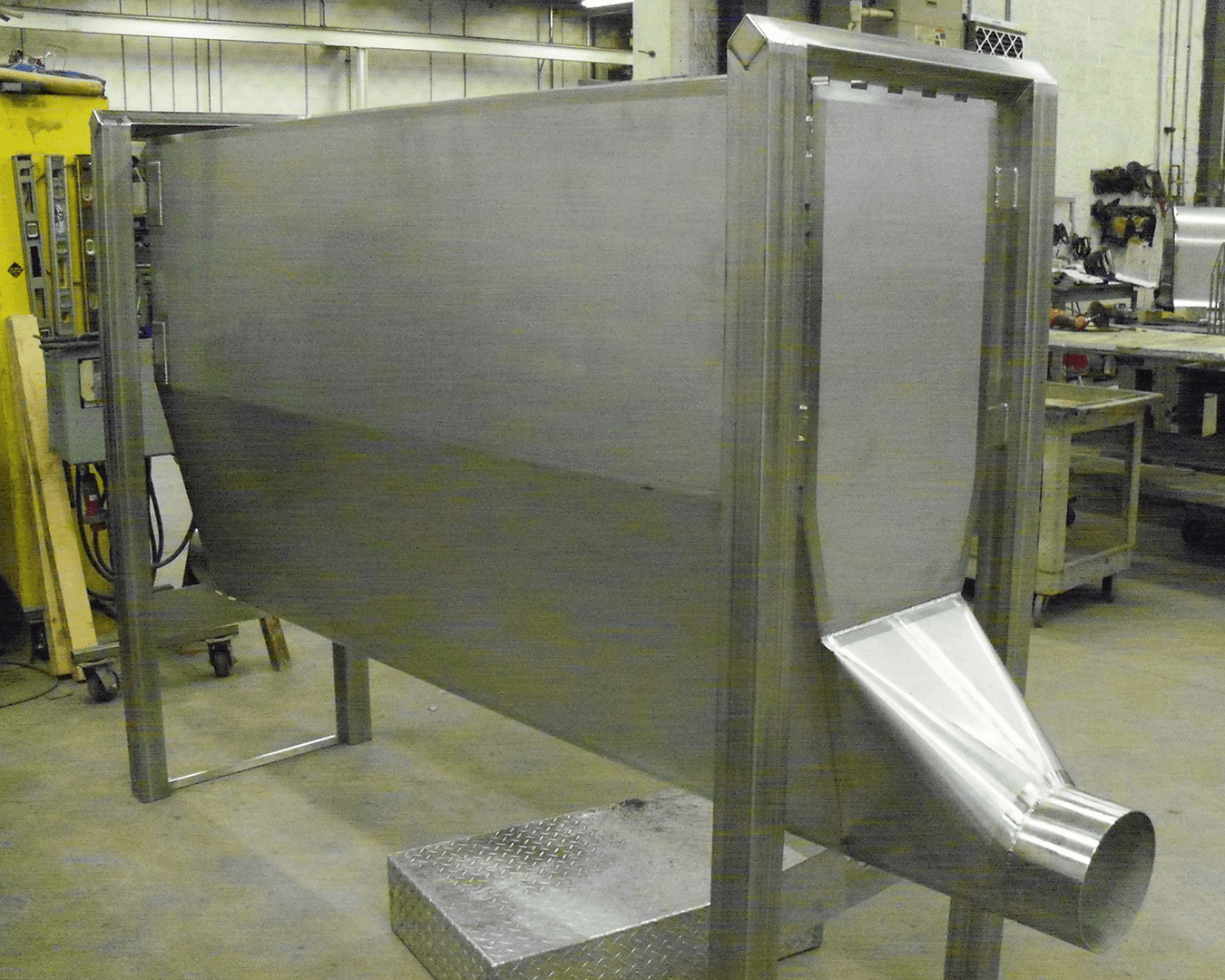

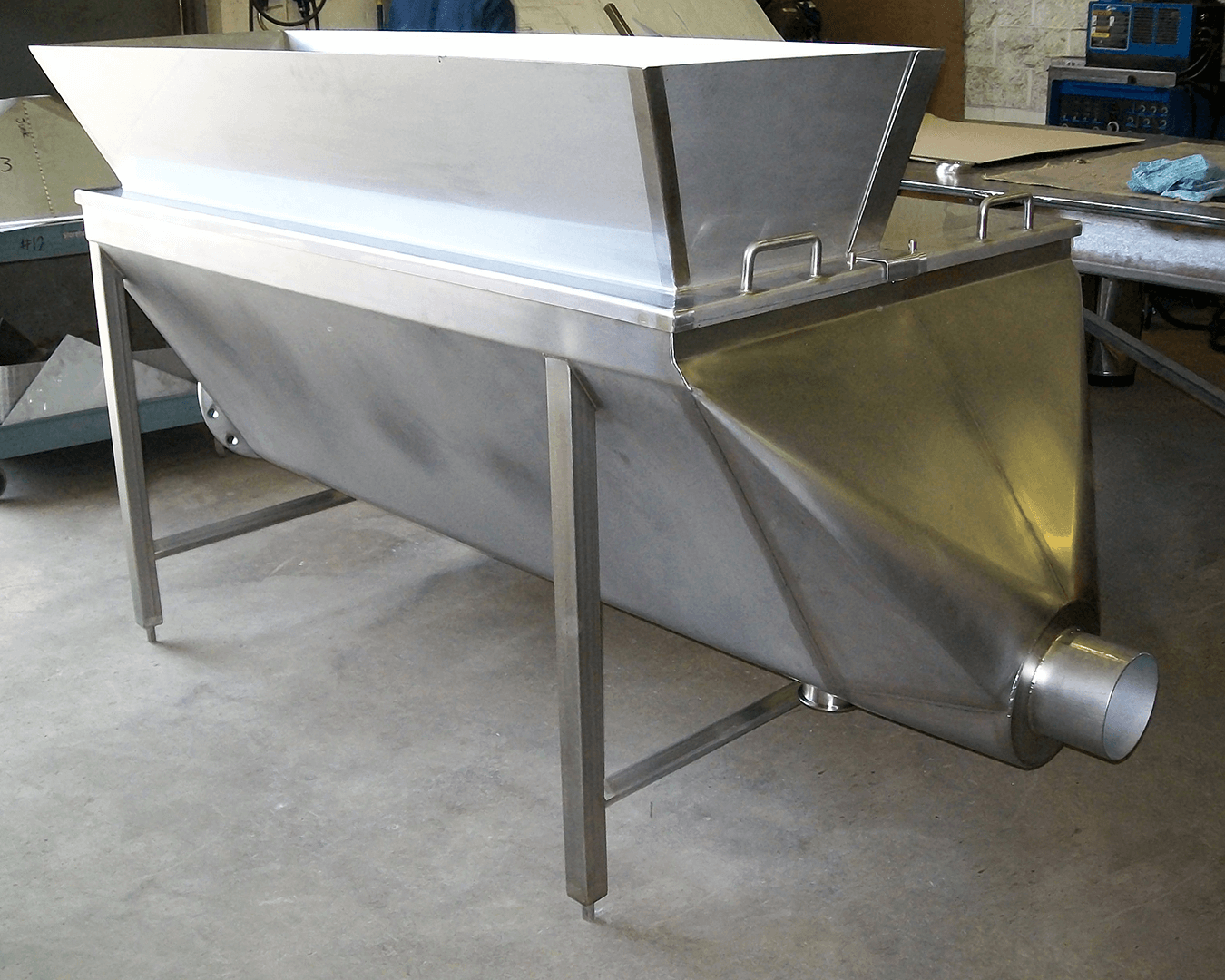

Pump Tanks & Product Flumes

Throughout many facilities assorted products are transported through process piping to get from one area to another. Flumes and pump tanks are necessary to introduce product into the process stream. SSi will custom build tanks and flumes per customer specifications. Inlet and outlet sizing as well as volume and shape are all customizable. Stainless steel construction with a 2B finish is normally used in a normal application but finish and material can easily be specified prior to design. Pump tank frames are typically designed with tubing rotated on a 45° angle to prevent any flat surfaces for water to pool on.

Design Capabilities

- Designed per customer specifications (flow, product, etc.)

- Type 304 stainless steel for wash-down purposes

- Used to introduce potatoes, shreds, cubes, or similar into a process pump stream

- Tapered tank bottom – pitches towards typical drain valve

- Optional connections for ultrasonic level detectors or Cla-Val™ control valves to regulate supply of make-up water

- Optional splash guards depending on application